Today, order fulfillment and logistics play a pivotal role in shaping e-commerce businesses.

Research indicates that the global e-commerce market is anticipated to reach $8.1 trillion by 2026. Modern customers expect their ordered product to be delivered within one or two days. Efficient logistics ensures a seamless flow of products throughout the supply chain, while order fulfillment ensures that ordered products are picked, packed, and shipped efficiently from the warehouse or fulfillment center. The product should reach the customer's doorstep as soon as possible. Business needs to prioritize logistics and fulfillment to improve its reputation in the market.

What Are Logistics And Fulfillment?

Logistics and fulfillment are two important processes of the supply chain. Both are highly essential for enhancing customer satisfaction and improving brand reputation.

Understanding the Logistics

Logistics manages the flow of goods from the point of origin to their destination. It ensures that the right products reach the right place and are in proper condition. Let's discuss with an example.

A shoe company orders raw materials from the suppliers and then transports them to the factories. It further transports the shoes to the warehouses for storage. The shoes are further shipped either to the retailer or directly to the customer. Logistics involve not only B2B transportation but also efficient storage and inventory management.

Understanding the Fulfillment

The order fulfillment process starts when the customer places an order on the marketplace or an e-commerce website. The order details are automatically sent to the nearest warehouse to the customer's location. The warehouse staff picks up the ordered product, thoroughly packages it, and then hands it to the shipping company. The shipper delivers the ordered product to the customer.

Let's discuss an example. A customer orders a mobile phone from an e-commerce company. The particular mobile phone is picked up from the nearest warehouse and shipped to the customer.

Why Logistics And Fulfillment Matter For E-commerce And Modern Retail?

Today, customers expect faster delivery of ordered products and a hassle-free returns process. Efficient logistics involve proper warehousing storage, and delivery, while innovative fulfillment systems involve quick order processing and dispatch.

Efficient logistics and fulfillment systems can improve the overall supply chain process and secure product journey. It even generates higher conversion rates, which means more customers are likely to place an order from the website. Again, customers are more likely to repurchase from the same website if they consistently receive their ordered products within the specified time and in good condition.

Difference Between Logistics and Fulfillment

| Aspect | Logistics | Fulfillment |

| Definition | It is a process of managing storage, transportation and delivery. | It involves processes of picking ordered products, packaging and shipping. |

| Scale | Broader scale. It means logistics can happen between both B2B and B2C businesses. | Narrow scale, Order fulfillment usually happens in a B2C business. |

| Product quantity | It involves bulk product movement from the factories to the warehouse. | It involves shipping a single ordered product from the warehouse to the customer's doorstep. |

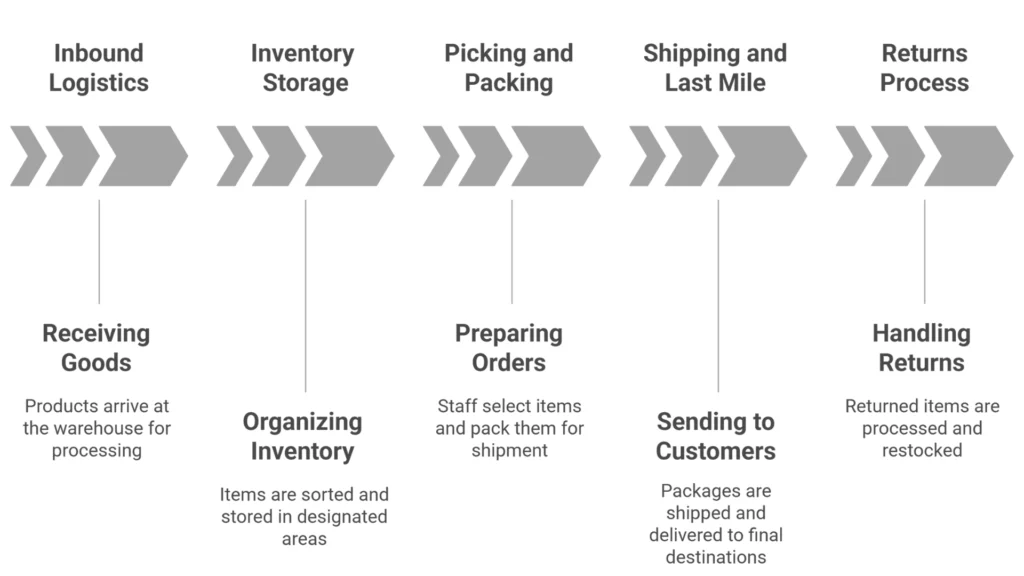

How Logistics and Fulfillment Works?

Here is a step-by-step guide on the working of logistics and fulfillment.

1. Inbound Logistics

The products from the factories are transported to the warehouse. The warehouse staff checks and inspects each product thoroughly to ensure it is not damaged and is as per the purchase orders.

2. Storage

The warehouse further stores the products in their designated places. Nowadays, most warehouses use advanced technology, such as a warehouse management and inventory management system, to optimize the warehouse layout and stock availability. Advanced software tracks stocks in real-time and helps with inventory planning, avoiding the problems of overstocking and understocking.

3. Picking And Packing

The warehouse staff picks up the ordered product from the shelf and does a thorough packaging so that it will not get damaged during transportation. The staff even put a shipping label on the package and included all the necessary details, such as the type of product inside, quantity, and more.

4. Shipping and Last Mile Delivery

The warehouse staff then selects the most suitable shipping carrier to deliver the packaged product to the customer. The staff compares the shipping rates of various companies and considers a few factors, such as shipment load, before choosing the shipping carrier. The shipping carrier delivers the product to the customer. Some shipping companies in India use route optimization software to deliver products faster to customers.

5. Returns

Sometimes the customer does not like the ordered product and places a return request. The staff of the warehouse company pick up the product from the customer and bring it back to the warehouse. The warehouse staff thoroughly inspects the product and then decides whether to restock, refurbish, or recycle it.

Explore Different Types Of Fulfillment And Logistics Models

There are various types of fulfillment and logistics models. They are in the list below.

1. In-House Fulfillment

Here, the business manages the entire supply chain process. The company has its own warehouse space for storing products. Whenever a customer orders a product, the company's staff picks it, does the packaging, and delivers it to the customer.

Pros

- Full control over all the operations

- Customises packaging, which improves brand reputation in the market.

Cons

- The company needs to invest a lot of money in building houses, managing staff, and equipment, which face difficulties in managing storage and logistics during periods of high demand.

- A slight delay in delivering products can have a negative impact on customers.

2. Third Party Logistics

Here, the business outsources logistics and fulfillment services to a 3PL company. The services include warehousing, inventory management, shipping, delivery, and returns.

Pros

- It saves the business costs.

- Third-party logistics providers typically offer scalable logistics solutions, enabling them to accommodate increased product demand when a business experiences sudden surges during holidays or specific seasons.

- Most third-party logistics providers offer advanced technology and softwares. This avoids the problems of inaccuracy in stocks and delivery.

Cons

- Less control over the packaging product.

- Any issues with a third-party logistics provider can have a negative impact on brand reputation.

3. Distributed Fulfillment

Here, inventories are stored in multiple warehouses, allowing for faster delivery to customers.

Pros

- It delivers products faster to the customer.

- Reduces the fuel costs of the business.

Cons

- Inventory management can be too complex. The business may require advanced software for managing inventories in various warehouse locations.

4. Centralised Fulfillment

Here, one central warehouse manages all aspects of the supply chain and logistics process.

Pros

- Easy to manage inventory

- Low operational costs.

Cons

- Longer delivery time

- High transportation costs, especially when delivering products to faraway customers.

5. Omnichannel Fulfillment Model

This model fulfills orders from various sales channels, including social media, app, website, and physical store, and provides a seamless customer experience across all channels. An omnichannel fulfilment model treats inventory as a single tool and is accessible to all the channels to reduce stockout issues.

Pros

- Fast order fulfillment

- Enhances customer satisfaction

Cons

- This model requires advanced software to integrate both online and offline channels, which can be costly for small and medium enterprises.

6. B2B Fulfillment Model

A B2B fulfillment model involves shipping products from one business to another in bulk quantities. The business can be a retailer, wholesaler, or distributor.

Pros

- Lower cost per unit while shipping.

Cons

- The business requires adequate space to store products in bulk quantities.

Technology, Tools, And Automation That Power Logistics And Fulfillment

There are various advanced software and technology tools that a business can utilize to power logistics and fulfillment.

- Warehouse Management System: It optimises the warehouse layout and speeds up the order fulfillment process of a business.

- Order Management Systems: It tracks customer orders from various channels, including the app and social media.

- Transportation Management System: It chooses the best and efficient route for transporting ordered products to the customers.

- Inventory Visibility Tools: It updates on the real-time availability of products across all storage locations.

- Conveyor Systems: It moves goods automatically to various locations in the warehouse.

- Robotics and Automated Guided Vehicles: Here, robots and automated guided vehicles transport goods automatically within the warehouse. Businesses can reduce labor costs by using robots in the warehouse.

- Integration and APIs: Integration and APIs connect fulfillment systems with e-commerce platforms like Flipkart and Amazon.

Fulfillment and Logistics Costs and Pricing Models

Typical Cost Buckets

- Storage Costs: These costs are associated with storing inventories in the warehouse.

- Handling Costs: It covers the cost of picking items from the warehouse and packaging them appropriately.

- Shipping Costs: It includes freight charges and carrier costs. The rate depends on the product's weight, delivery speed, and shipping location.

- Return Processing: It covers costs for product inspection, restocking, repackaging, and recycling.

Pricing Models

There are various types of pricing models. Here is a list of them below.

- Per Order/Per Unit Pricing: Here, the business needs to pay a fixed amount when the staff pick each ordered product and package it. It is best for small and medium enterprises.

- Per Pallet/Per Cubicfoot Pricing: Here, the business owner has to pay fees based on the space occupied in the warehouse. It is best for a business that deals with slow-moving products.

- Monthly Fee Model: Here, a business owner has to pay an affixed amount per month for storing products and handling them.

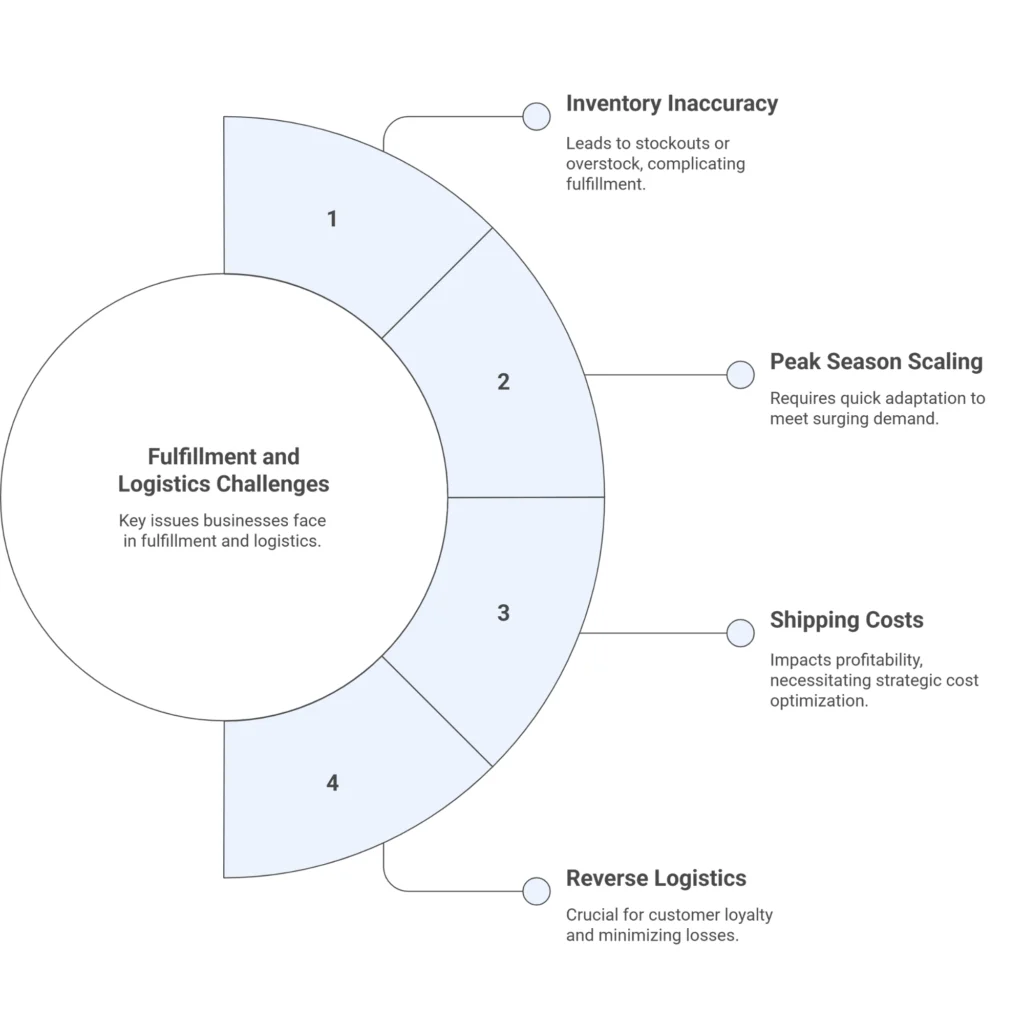

Common Fulfillment And Logistics Challenges

Businesses dealing with the Order fulfillment process and logistics face a lot of challenges. Here is a list of them below.

1. Inventory inaccuracy

Inventory accuracy, especially between physical stocks and data filed into the system, can lead to overstocking or understocking issues in a business.

Third-party logistics providers use advanced softwares like data analytics and inventory management to track each inventory movement in the warehouse. It reduces errors and enhances customer satisfaction with the business.

2. Peak Season Scaling

Order volumes can increase during a particular season or holiday. It can be challenging for a small or medium-sized enterprise to manage on its own. Partnering with a 3PL provider can have various advantages, such as offering scalable warehouse solutions, which means they can easily accommodate products and manage the order fulfillment process smoothly during peak season or holidays.

3. Shipping Costs

Shipping costs are one of the significant problems for an e-commerce company. The fuel charge increases when delivering to customers who are far away. Partnering with a 3PL provider can reduce a business's shipping costs. 3PL Companies uses advanced software and chooses the best route for product delivery. They even have a partnership with multiple shipping carriers and choose the most affordable rate for each destination.

4. Reverse Logistics

Reverse logistics can be too complex for small and medium enterprises. A 3PL partner collects the product back from the customer and thoroughly inspects it. It restocks, refurbishes, or recycles after thorough inspection of the product.

How To Choose The Best Logistics And Fulfillment Partner?

There are various logistics and fulfillment partners. But all of them do not provide the same warehousing storage services. A business needs to consider a few factors, as follows.

1. Technology And System Integration

The logistics and fulfillment partner should integrate with advanced technology like a warehouse management system and inventory management system to optimize the order fulfillment process.

2. Geographical Coverage

The logistics and fulfillment company should have multiple fulfillment centers in India so that it can deliver faster to the customers.

3. Price

The business needs to compare the prices of various logistics and fulfillment partners and choose the one that provides excellent services at an affordable cost.

4. Experience and Industry Expertise

The logistics and fulfillment service provider should have experience related to your industry. It should have good reviews and positive testimonials.

Conclusion

Order fulfillment and logistics are the backbone of a business. They are essential for business growth and enhance customer satisfaction. A business can choose the right fulfillment model, like in-house, 3PL, or omnichannel, depending on the scale and order volume.