Inventory Cycle Counts are regular checks and counts of a small portion of inventory, done on a rotating schedule, instead of counting everything at once. It helps businesses keep track of stock levels accurately without stopping daily operations.

A 2023 research report says that inventory inaccuracies lead to stockouts, overstocking, and customer dissatisfaction in most businesses.

Counting all the inventories by shutting down the primary warehouse operations for a single day is not a good practice for companies. Hence, businesses should utilize the inventory cycle counting procedure, i.e, counting inventories in small and manageable portions performed daily, weekly, or monthly.

What is Inventory Cycle Count?

Inventory cycle counting is an inventory auditing procedure where the staff counts a small group of inventories on a specific day and time without disrupting the logistics operation flow. Regular inventory counts can identify the discrepancies and enable the company to take necessary steps to resolve them. It even ensures the right inventory is always in the warehouse to meet customer demands. The staff does the inventory cycle counts daily, weekly, or monthly based on their value and frequency of movement.

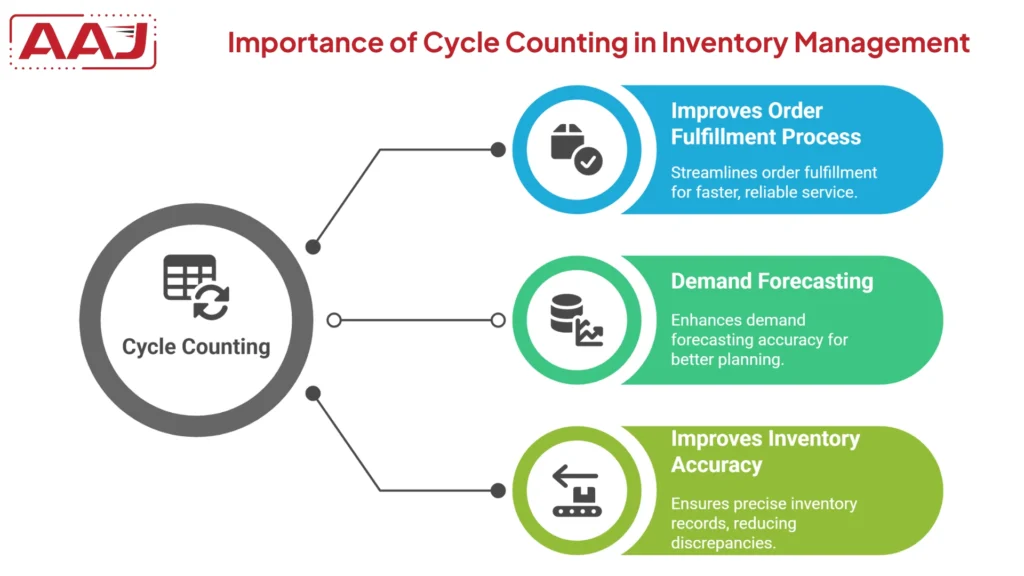

Importance of Cycle Counting in Inventory Management

Cycle counting plays a vital role in a business's supply chain operations. Here is a list of them below.

1. Improves Order Fulfillment Process

Regular cycle counting ensures there is always product availability in the warehouse storage. The staff can easily pick up the ordered product, do the packaging, and hand it over to the shipping company. Thus, the cycle counting process improves the order fulfillment process of the business and enhances customer satisfaction.

2. Demand Forecasting

Regular inventory cycle count enables businesses to forecast product demand in the near future. It even allows businesses to decide when and how much to order products.

3. Improves Inventory Accuracy

Inventory cycle counting identifies discrepancies and maintains accurate data. It even avoids the problem of overstocking and out-of-stock issues.

Physical Count Vs. Cycle Count - Major Differences

- Physical counting means counting all the inventories once or twice a year. Cycle counting involves counting inventories daily, weekly, or monthly.

- Physical counting involves more supply chain disruptions. The business must close order fulfillment or other necessary operations during physical counting. Cycle counting does not include many disruptions.

- Physical counting is not very accurate. However, cycle counting allows you to count inventories in batches over time that provide more accurate data.

Different Types of Cycle Count Inventory Process

There are various cycle count inventory processes. Here is a list of them below.

1. ABC Inventory Analysis

ABC inventory analysis is one of the most popular methods of cycle counting. The warehouse staff classifies items based on their value.

- Class A: These items are highly valuable and fast-moving. They hold only 10 percent of the total inventory stored in the logistics warehouse.

- Class B: These items are less valuable compared to class A items. They hold only 20 percent of the total inventory stored in the warehouse.

- Class C: These items are less valuable than class A and class B items. They hold 70 percent of the total inventory in the warehouse.

2. Random Sample Cycle Counting

Random sample cycle counting is a good option if a business has numerous similar inventories. The company can choose a random number of products during each cycle count. It causes a few disruptions, as it can happen in regular business hours.

Benefits of Inventory Cycle Counts

- Regular inventory cycle count ensures the records match the physical stock.

- Overstocking can raise business stock holding costs, whereas understocking can dissatisfy customers. A regular inventory cycle count can avoid problems of overstocking and understocking.

- When a business frequently counts inventories in small numbers, it is easy to manage and causes fewer disruptions.

- Inventory cycle count improves the business's order fulfillment process.

Best Practices Of Cycle Counting In Inventory Management

- Categories inventory items based on Class A, B, and C and their value.

- The business should establish a consistent schedule for counting inventories. For example, it should calculate class A items every month.

- The business should develop detailed guidelines on the cycle count procedure, such as item selection and documentation.

- Ensure the staff store the inventories in the proper place with correct labels.

- Experienced and trained staff should follow the cycle counting procedure. They should carry out the procedure only during the low activity periods.

- The business can use barcode scanners and RFID to streamline the cycle counting.

Final Words

Traditional physical counting disrupts the operations of a business and can lead to hidden errors. But cycle counting enables counting a small group of inventories daily, weekly, or monthly.