A warehouse plays a vital role in supply chain operations. But research says that slow-moving inventories or deadstock occupy 20 to 30% of the warehouse space.

Deadstock is inventory that sits on warehouse shelves for months and has little or no market demand. It increases the business's storage costs and decreases order-picking efficiency. Businesses should utilize advanced technology to track slow-moving inventory and use various practices, such as offering special discounts or bundling with valuable products, to clear deadstock.

What Is Deadstock?

Deadstock means unsold inventory that has been in the warehouse for a long time. These inventories take up valuable warehouse space and increase the business's holding costs.

Dead stock can include damaged or leftover seasonal products in the warehouse. Perishable products, such as food or medicine, can become deadstock if they are not sold within a specific period.

A business owner does not mark the inventories as dead stock overnight. Now the question comes, then at what point are they considered deadstock? The business first categorises them as slow-moving inventory, and if they remain unsold after 1 year, it considers them deadstock.

Let's discuss with an example.

A retailer has sweaters and winter coats in its warehouse even after the winter season has ended. The customer has shifted towards ordering spring clothes. Now, the sweaters and winter coats are lying dead in the ecommerce warehouse.

Differentiate Between Slow-moving Stock, Deadstock & Obsolete Stock

Slow-Moving Stock

These stocks are sold to the customer, but they move very slowly from the warehouse.

Deadstock

These stocks have been lying in the warehouse since they entered. The business owner offers discounts on these products, but customers still aren't interested in buying them.

Obsolete Stock

These stocks are outdated or have almost no market demand.

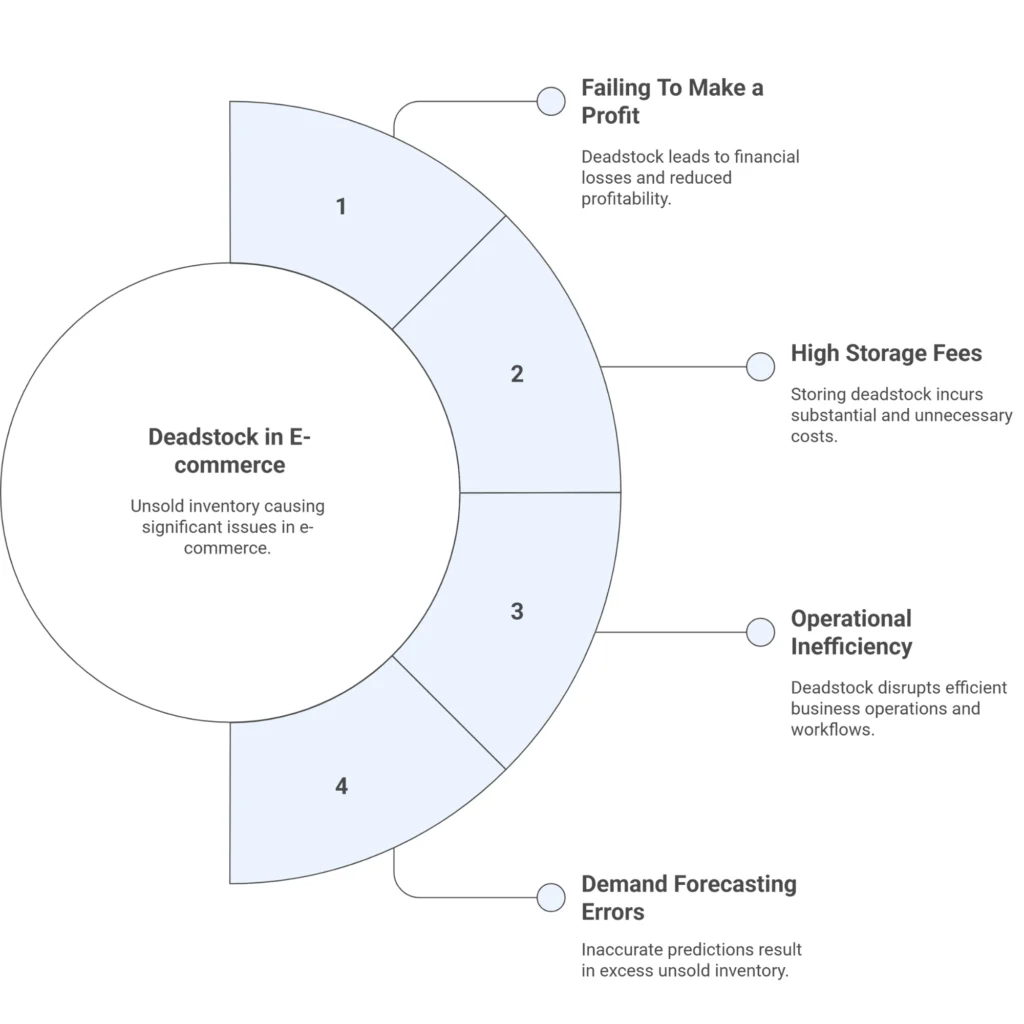

Why Deadstock Is A Serious Problem In E-commerce Business?

Deadstock is a serious problem for e-commerce businesses because of the following reasons.

1. Failing To Make a Profit

Deadstock was initially purchased with the intent to sell to customers. But if the business owner cannot sell them, then it is not making a profit.

2. High Storage Fees

Dead stock takes valuable space in the warehouse and increases the storage costs of the business. The business owner will also have less space for storing demanding inventory.

3. Operational Inefficiency

Deadstock clutters the shelves in the warehouse. The staff find it challenging to pick ordered products, which can delay ecommerce fulfillment.

4. Demand Forecasting Errors

Deadstock can lead to demand forecasting errors, which can cause overstocking or understocking issues.

Common Causes Of Deadstock

1. Poor Demand Forecasting

A business owner cannot always accurately forecast demand. Flawed data or unrealistic expectations can cause poor demand forecasting. If a business owner overestimates product demand and produces a lot of inventory that isn't sold, it falls into the category of deadstock. This is one of the major problems of having dead stock in the warehouse facility.

2. Lack Of Real-Time visibility

The lack of real-time visibility means the business owner cannot properly track stock in the warehouse or identify products in excess. This can lead to dead stock issues in the warehouse.

A business owner can use advanced technologies, such as inventory management software, to avoid this issue. The software will help track and monitor all products in the fulfillment center and support accurate decision-making.

3. Seasonality Or Trend Changes

Seasonality or trend changes are among the significant causes of deadstock issues in a business. For example, winter wear or festive items are in demand only in certain months. If the business overstocks these products and cannot sell them within a specific time frame, then they lie in the warehouse for months and are finally categorised as deadstock. Again, if customer preferences change suddenly, previously popular products may sit in the warehouse for several months and be classified as deadstock.

4. Product Quality Issues

If products have defects or poor quality and fail to meet customer expectations, they remain unsold for several months and are classified as deadstock. Product quality issues occur because of improper manufacturing or inspection. Proper quality checks during the manufacturing process can help address this problem.

5. Ineffective Marketing Or Promotions

Sometimes a business owner has a high-quality product, but cannot promote it properly in the market. Again, improper product descriptions and inconsistent promotional strategies can reduce product demand. Hence, the products remain in the warehouse for several months and enter the deadstock category.

6. Supply Chain Disruptions

Supply chain disruptions, such as natural disasters or strikes, can delay the arrival of products in the warehouse. If the product arrives after the festive season, customers will no longer be interested in buying it. The products sit in the warehouse for various months and ultimately come into the deadstock category.

Best Practices To Manage And Reduce Deadstock

A business owner can adopt a few practices to reduce deadstock in the warehouse.

1. Reevaluate Purchase Decisions

Reevaluating purchasing decisions is one of the best ways to reduce deadstock. A business owner should review supply orders, compare actual sales with forecasted demand, and buy only the necessary inventory.

2. Implement Forecasting Tools

A business owner can use forecasting tools to study past sales trends and customer behaviour. These tools can help avoid buying too many products from the seller.

3. Run Clearance Sales Or Promotions

Slow-moving products take up unnecessary space in the warehouse and reduce order-picking efficiency. A business owner can offer discounts or special deals on slow-moving products and sell products that are stuck in the warehouse. The business owner will earn less profit from it, but it will free up warehouse space and reduce storage costs. It even improves the business's cash flow.

4. Bundle Slow-Moving Products

A business owner can bundle slow-moving products with fast-selling products and sell them to customers at a special price. It will help a business to clear the slow-moving products quickly from the warehouse. Customers will also think they are getting more value at a lower price and will be interested in buying.

5. Liquidate Or Donate Unsellable Goods

Liquidating goods means selling unsold products at very low prices to wholesalers and retailers. Donating products to charities is even a good option. It will free up warehouse space and increase order fulfilment efficiency.

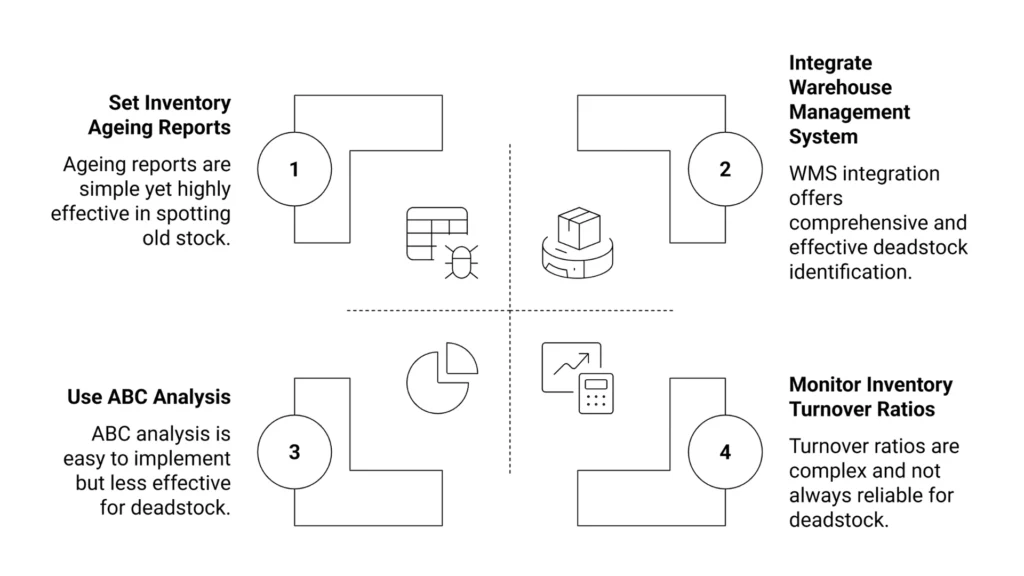

How To Identify Deadstock In Your Warehouse?

1. Set Inventory Ageing Reports

The ecommerce business owner should track products in the 3PL ecommerce fulfillment center and identify those that have been lying for 6-8 months. The business can categorise them as deadstock.

2. Use ABC Analysis

The business owner can classify products into Class A, Class B, and Class C. Class A includes highly valuable stocks and requires tight control. Class B items include stocks that are not as useful as class A items and require moderate control. Class C includes slow-moving products. If these products sit in a warehouse for 6 months to 1 year, the business owner can classify them as deadstock.

3. Monitor Inventory Turnover Ratios

A business owner should monitor inventory turnover ratios regularly. A low inventory turnover ratio indicates that products are sitting in the warehouse for a longer time and can lead to deadstock.

4. Integrate Warehouse Management System

A business owner can use advanced technologies, such as a warehouse management system. It not only optimises the warehouse layout but also tracks products stored in the warehouse in real time. WMSs can make inventory control easier and help businesses identify slow-moving products.

How To Prevent Deadstock In the Future?

- Businesses should use real-time inventory tracking software to identify slow-moving products in the warehouse. Knowing exact stock levels even helps a company to avoid overstocking products.

- Businesses should implement the just-in-time method to avoid deadstock.

- Businesses should use advanced technologies such as AI and machine learning to forecast product demand and avoid dead stock accurately.

- Businesses can use inventory management software such as Zoho Inventory, Easystock, and Stockpile to track deadstock.

Final Words

Businesses store their inventory in their warehouses. But certain stocks sit on the shelves for months and have almost no market demand. They are known as deadstock. Businesses can identify deadstock using ABC analysis, monitoring the inventory turnover ratio, and leveraging advanced technologies such as a warehouse management system. It can then clear the deadstock by providing discounts or donating it to charity.