The Indian logistics market was USD 228.4 billion in 2024 and is expected to reach USD 357.3 billion by 2030. This shows the rapid growth of the logistics market in India. It is mainly because of the development of various industries and the contribution of top logistics companies in India.

Supply chain and logistics are the pillars of a business. Supply chain involves everything from procuring raw materials to delivering products to customers, while logistics involves storing and transporting them efficiently to the destination.

A company needs to choose reliable suppliers and adopt advanced technology to manage the supply chain and logistics efficiently. Small and medium enterprises may face issues in building infrastructure or managing storage. They can choose a supply chain and logistics partner to manage various supply chain and logistics activities and enhance customer satisfaction.

What Is Supply Chain And Logistics?

Supply Chain Overview

Supply chain is a network of activities and technology involved in producing goods and selling them to customers. It covers various things like procuring raw materials, converting them to finished goods, warehousing and storing them, distributing them, and finally delivering goods to the customer.

For example, let's discuss the supply chain network of the smartphone industry. The Company first procures materials like screens and batteries from the suppliers and then sends them to the manufacturing unit for assembly. The smartphones are further distributed in regional warehouses, and from there they are transported to retailers.

So the entire supply chain network depends on suppliers, manufacturers, and retailers. Any disruption in the network, like the late delivery of raw materials, can disturb the whole supply chain process and have an adverse effect on the brand reputation in the market.

Logistics Overview

Logistics is a part of the supply chain that involves managing the flow of goods and services and transporting them to their destination. So logistics involves warehousing, inventory management, packaging, order fulfillment, and distribution.

Let's discuss an example. When a customer orders a smartphone from a website, the warehouse picks the requested product, does packaging, and hands it to the shipper. The shipper delivers the product to the customer. The entire movement of a product from the warehouse to the customer's doorstep is known as logistics.

Logistics is of two types: inbound and outbound logistics.

1. Inbound Logistics

Inbound Logistics deals with the movement of goods into a business, like receiving raw materials from the suppliers.

2. Outbound Logistics

It involves the movement of goods from the business to the customer, like transporting goods from the warehouse to the customer’s doorstep.

Difference Between Supply Chain & Logistics

| Features | Supply Chain | Logistics |

| Definition | It involves the entire network, like procuring raw materials, manufacturing, warehousing, distribution, and transportation. | It involves managing goods and services and distributing them to the final destination. |

| Objective | To properly coordinate with suppliers, manufacturers, and retailers, and enhance customer satisfaction. | Timely, cost-effective transportation and delivery. |

Importance Of Supply Chain And Logistics In Global Trade

- An efficient supply chain reduces the warehousing and transportation costs of the Company.

- An efficient logistics system ensures that goods reach their destination quickly and efficiently.

- Various business owners procure raw materials from one country, manufacture and sell them in another country. So an efficient supply chain and logistics connect globally.

- An efficient supply chain can manage risks appropriately, like natural disasters, sudden market demand, and many more.

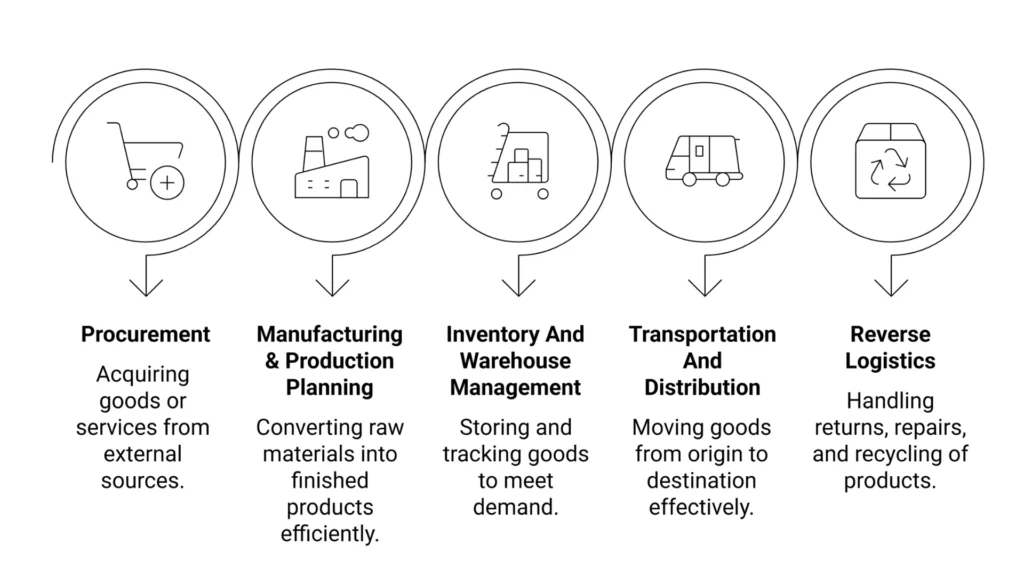

Key Components Of Supply Chain And Logistics

The components of the supply chain and logistics are as follows.

1. Procurement

It involves identifying the reliable suppliers in the market so that they can supply the raw materials on time and in good condition.

2. Manufacturing & Production Planning

It focuses on converting raw materials into finished goods.

3. Inventory And Warehouse Management

It involves storing inventories in the warehouse. Nowadays, most of the warehouses use advanced technology like a warehouse management system to optimize the layout and order fulfillment process.

4. Transportation And Distribution

It involves transporting goods from one place to another. Today, most of the business owners use a transport management system to choose the efficient route and reduce fuel costs.

5. Reverse Logistics

Reverse logistics deals with the flow of goods from the customers to the warehouse.

Common Challenges In Supply Chain & Logistics

Supply chain and logistics offer various challenges. They are in the list below.

1. Global Disruptions

Global disruptions like pandemics, port congestion, wars, and strikes can delay shipments. It can adversely affect customer satisfaction.

2. Rising Freight Costs

Transportation costs can increase because of an increase in fuel costs and handling fees. It can reduce the profit margins of the business.

3. Lack Of Visibility

Many business owners struggle to track goods because of a manual process or a lack of advanced technology, like a warehouse and inventory management system.

4. Sustainability

Today, most warehousing companies are under pressure to make environmentally friendly packaging or to refurbish. It even increases the operational cost of the business.

Strategies To Optimize Supply Chain And Logistics

Here is a list of a few strategies to optimise supply chain and logistics.

1. Demand Forecasting & Planning

Demand forecasting involves forecasting product demand in the near future to avoid problems of overstocking and understocking. Businesses should study past sales trends and market or use historical sales data or AI to forecast product demand.

2. Building Resilient Supply Chain

Businesses should focus on building a resilient supply chain to withstand disruptions and operate smoothly even during a crisis. For example, the company should connect with a lot of reliable suppliers. If one supplier has issues in delivering raw materials, then the other supplier can fulfill it on time. Businesses should also keep buffer stock on hand to meet customer needs if there is sudden product demand in the market.

3. Partnering With The Right 3PL

Small and medium enterprises can face challenges in storing inventories and managing the entire supply chain and logistics efficiently. They can form a partnership with a right third-party logistics provider. The provider will store inventories and even pick, pack, and ship the ordered products. But businesses should choose the third-party logistics provider by considering factors like its express, scalability, access to technology, and a few more.

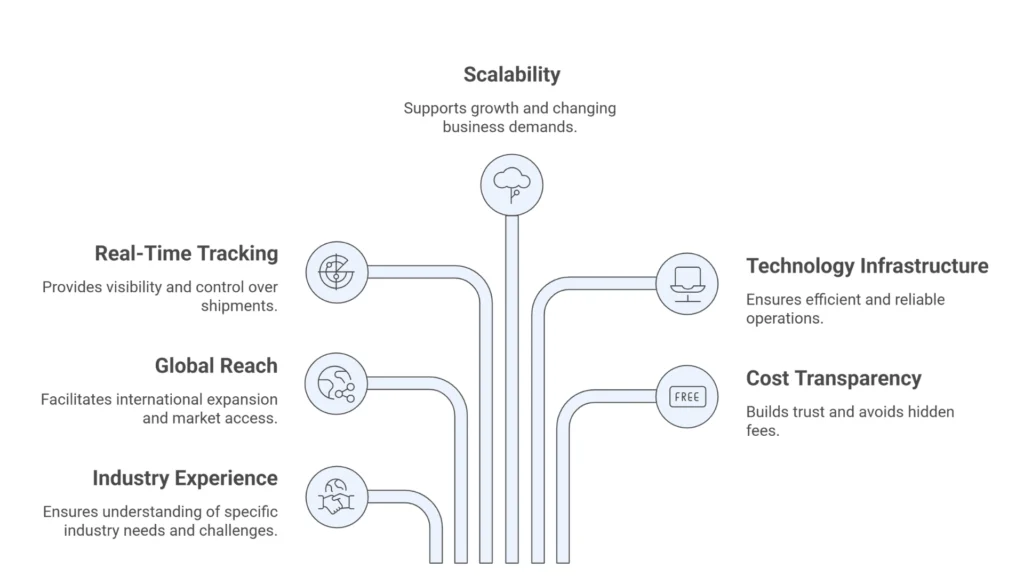

How To Choose The Right Supply Chain And Logistics Partner?

There are various supply chain and logistics partners. But choosing the right partner ensures deliveries on time and enhances customer satisfaction. Here are a few factors that businesses should consider while choosing the proper supply chain and logistics partner.

1. Experience In Your Industry

A business should choose the supply chain and logistics partner that has experience in its industry. It ensures that the 3PL partner will handle and store the product effectively.

2. Pan India Or Global Reach

The business should look for a partner which has a wide logistics network. It reduces B2B transportation costs and ensures faster deliveries to the customers.

3. Real-Time Tracking And Visibility Tools

A business should look for a partner that has real-time tracking and visibility tools. It allows a business owner to monitor goods movement at every stage of the supply chain and plan accordingly to avoid high holding costs, dead stock, or under-stocking issues. Customers can get updates about the location of their ordered product and when they can expect the order. This improves trust and satisfaction in customers.

4. Scalability For E-commerce Growth

The supply chain and logistics partner should provide scalable warehouse solutions, which means it can accommodate products when the business experiences a high product demand in a particular festival or holiday.

5. Proven Technology Infrastructure

The partner should leverage advanced technology like a warehouse management system, transport management system, automated sorting, and picking to reduce errors and speed up 3PL ecommerce fulfillment.

6. Cost Transparency

A business should always look for a partner that provides a clear and detailed breakdown of fees related to warehousing, order fulfillment, and transportation. The partner should not keep any hidden costs, as it can increase the expenses of the business.

Future Of Supply Chain And Logistics

- Automation will play a significant role in the supply chain and logistics industry. Most of the businesses will embrace AI, robotics, machine learning, drone deliveries, and automated conveyor systems to reduce errors and speed up the order fulfillment process.

- Most of the businesses will use AI to forecast product demand accurately.

- Businesses will use IOT and sensors to monitor product movement and their conditions every time.

- Most of the businesses will focus on environmentally friendly packaging or while refurbishing products. They will utilize electric vehicles in transporting goods from one place to another to reduce carbon emissions.

- Most of the businesses will utilize dark stores or microfulfillment centers to deliver products faster to the customers.

- Businesses will utilize blockchain technology to track product movement and prevent fraud.

Common Mistakes To Avoid In Supply Chain Management

- If the business cannot predict product demand correctly, then it can lead to overstocking and understocking issues.

- If the business depends on a single supplier, then it can be quite risky. If the supplier delays in delivering products, then it can adversely affect the entire supply chain.

Final Words

Supply chain and logistics form the backbone of a business. Businesses can utilize advanced technology like a warehouse management system or AI to maximize supply chain efficiency. An efficient logistics and supply chain can reduce holding and transportation costs. It even avoids the problem of overstocking and understocking issues.