Inventory holds a large portion of business assets. But managing and inventory planning manually in this competitive world is quite challenging for businesses. Overstocking products can increase storage costs. Few products can even expire with time. Simultaneously, understocking products can lead to sales loss. Poor visibility of products can make it difficult for the business to predict product demand in the near future.

Proper inventory planning and control play an important role in the supply chain. They ensure inventories are sufficiently available to meet customer demands or reduce holding costs as well. Businesses use various advanced software, such as a warehouse management system and an inventory management system, for proper inventory planning.

What Is Inventory Planning? Understanding Its Meaning And Importance

Inventory planning involves finding out the exact amount of stock to keep in the warehouse facilities to meet customer demands effectively, along with reducing the inventory holding costs. Businesses need to use advanced technology or analyze the current and past sales data and replenish products accordingly.

Proper inventory planning avoids problems of overstocking and understocking in a business. It even enhances customer satisfaction and improves brand reputation in the market.

Difference Between Inventory Planning And Inventory Control

Inventory planning ensures the right amount of stock is always available in the warehouse at the right time to meet customer demand effectively. But inventory control involves managing the existing stock in the warehouse effectively.

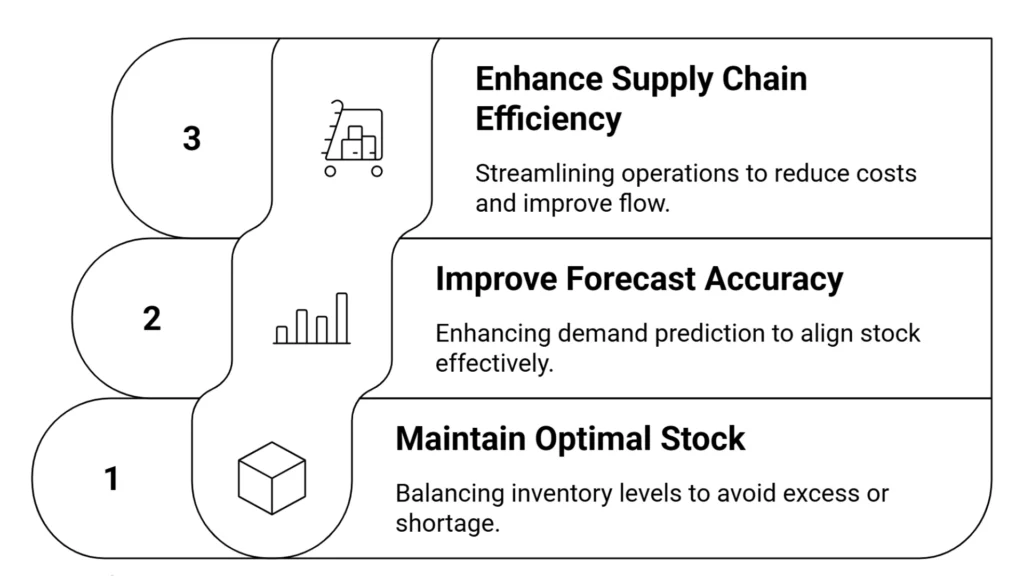

The Objectives Of Inventory Planning

1. Maintain Optimal Stock Levels

If a business keeps too much of the stock in the warehouse or fulfillment hub, then it raises holding costs. Keeping too few inventories leads to missed sales opportunities and decreases customer satisfaction. Inventory planning involves keeping the right amount of inventory in the warehouse to fulfill customer demands. It avoids stock issues in a business.

2. Improve Forecast Accuracy

Inventory planning involves a thorough analysis of market conditions and past sales data, and then predicting product demand accordingly. It avoids last-minute stock shortages in a business.

3. Improves Supply Chain Efficiency

A well-executed inventory planning improves the overall supply chain operations efficiency of the business. It ensures the right time of procuring raw materials, manufacturing products, and storing them in the warehouse.

Inventory Planning Process-Step-by-Step Guide

Here is a step-by-step guide on the inventory planning process.

1. Demand Forecasting

The first step of the inventory planning process is demand forecasting. It involves analysis of market trends, historical sales data, and customer behaviour to predict product demand effectively.

2. Setting Inventory Policies

It involves creating proper rules and guidelines on when the inventories will be ordered to avoid overstocking and understocking issues. Inventory policies include reorder point (the point at which the business needs to reorder the inventory to prevent stockout issues), lead times(the maximum time required to order the product and its arrival at the warehouse), and a few more.

3. Safety Stock Calculation

Safety stock is extra stock kept in the warehouse to prevent stockout issues. Businesses need to calculate the safety stock based on factors like demand variability and supplier lead times.

4. Supplier Coordination

The business maintains strong collaboration with suppliers to ensure products are available on time and have a smooth order fulfilment process.

5. Continuous Monitoring And Adjustment

Businesses need to monitor key metrics like inventory turnover rate, holding cost, and order fulfilment rate. It should then identify the areas that require improvement.

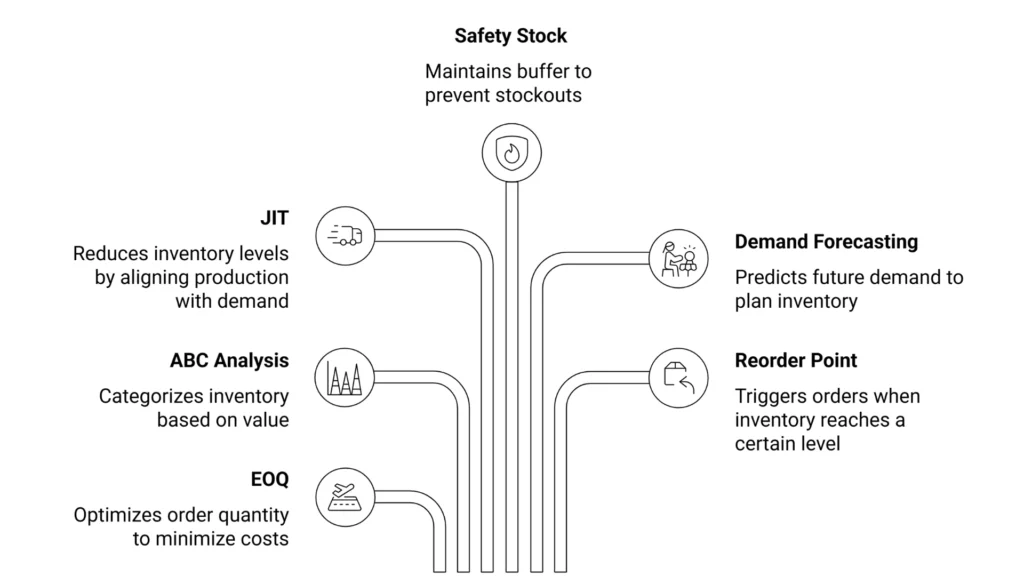

Inventory Planning Methods And Techniques

Businesses need a few methods and techniques to have effective inventory planning and control. Some of the methods are as follows.

1. EOQ (Economic Order Quantity)

It is a mathematical formula that finds the ideal quantity of products needed to be stored in the warehouse and avoids problems of holding costs.

EOQ = √(2DS / H)

D = Annual demand

H =Holding cost per unit per year

S = ordering cost

2. ABC Analysis

ABC analysis divides the stock stored in the warehouse into almost three categories.

Class A items: They are highly valuable items and require close monitoring.

Class B Items: They are less valuable compared to class A items. But still, they require close monitoring to have smooth order fulfilment.

Class C Items: They are of low value compared to class A and class B items and do not require much monitoring. But they represent a larger portion of the inventory in the warehouse.

3. JIT (Just In Time)

The just-in-time inventory concept involves ordering products and materials when required rather than maintaining a large amount of inventory in the warehouse. The main objective of the JIT concept is to reduce wastage and storage costs of the business. Businesses can adopt the JIT method and quickly adapt to market changes.

4. Safety Stock Analysis

Safety stock analysis involves maintaining optimal stock in the warehouse to prevent stockout issues, especially when the product demand suddenly increases in the market.

5. Demand Forecasting Models

Here, the business needs to either follow a qualitative or a quantitative approach to estimate product demand in the near future.

6. Reorder Point

It determines the exact stock level at which the business needs to place a new order to avoid stockout issues.

Reorder point = (Average daily usage × leadtime) + safety stock

Tools And Software Used By Inventory Planners

Inventory planners use various software to optimize the inventory level in the warehouse. Some of the tools and software are as follows.

- Enterprise Resource Planning Systems: ERP systems integrate numerous functions of business, like procurement, inventory, and sales, in one single platform.

- Warehouse Management System: It optimises the entire layout of the warehouse and speeds up order fulfilment operations like picking, packaging, and shipping.

- Inventory Management Software: This software tracks, manages, and updates the inventory level inside the warehouse.

- Barcode and RFID Systems: They track product movement in the entire supply chain.

Inventory Planning And Control Strategies For Business Growth

- A business should do the inventory planning according to its business objectives. For example, a retail business should give more importance to product availability to meet customer demands.

- A business should implement modern warehouse forecasting tools and techniques to track stock movement or predict future demand for the product in the market.

- A business should coordinate with various departments like procurement, sales, production, and logistics to make decisions related to lead times and stock levels.

- A business should use a centralised inventory management system to track and manage stock levels in various warehouses.

- The business should track inventory turnover rate and order accuracy to identify weak areas of inventory management.

Common Challenges and Mistakes In Inventory Planning

A business can face a few challenges while doing inventory planning. Some of them are in the list below.

- One of the biggest challenges while doing inventory planning is forecasting product demand. Overestimating the product demand can increase the holding costs, while underestimating product demand can have a negative impact on customers.

- If the business struggles with real-time visibility of the products, then it may lead to unfulfilled customer orders.

- When there is miscommunication between the sales, procurement, and logistics teams, it can lead to supply chain inefficiency. It may lead to overordering or a shortage of products in the warehouse.

- If the business relies on manual inventory tracking methods, then it leads to inefficiencies or data errors.

- If the business keeps a lot of inventory in the warehouse, then it increases the warehousing costs. The products can become obsolete or expire with time.

Final Words

Effective inventory planning is the foundation of supply chain management. A business can use modern tools and technologies for proper inventory planning and control, and reduce wastage and costs. It even helps a company to improve supply chain efficiency and enhance customer satisfaction.