Inventory optimization is a strategic process of maintaining the right amount of stock in the warehouse at the right time to fulfill customer demand. Its main goal is to reduce storage costs and fulfill customer demands consistently.

Balancing supply and demand is quite important in a supply chain and logistics company. Overstocking products can increase carrying costs, while understocking can result in loss of sales.

What Is Inventory Optimization?

Inventory optimization is a process of maintaining the right amounts of goods in a warehouse to meet customer demands while reducing wastage and storage costs.

Overstocking products in the warehouse ties up capital and increases the storage costs of the business. Again, understocking can dissatisfy customers and lead to lost sales opportunities. Inventory optimization is a strategic approach that uses advanced tools like AI and machine learning to optimize stock levels in the warehouse.

Many people think that inventory management and inventory optimization are the same thing. But in reality, they are different. Inventory management focuses on day-to-day stock operations inside the warehouse, like receiving stock, storing it, and tracking it in real time. But inventory optimization ensures that the right level of stock is always inside the warehouse to meet customer demand. It aims to reduce storage costs, wastage, and balance supply and demand.

Why Inventory Optimization Is Crucial For Supply Chain Success?

1. Reduces Working Capital and Carrying Costs

Excess inventories tie up capital that businesses can invest in product development or while exploring new markets. Inventory optimization reduces the working capital and storage costs of the business.

2. Lower Stockouts

Stockout problems can create dissatisfaction in customers. It adversely affects brand reputation in the market. Inventory optimization reduces stockout issues.

3. Faster Order Fulfillment

Inventory optimization speeds up warehouse operations and enables same-day or next-day delivery to customers.

4. Smoother Production Scheduling

Inventory optimization ensures raw materials and components are always available when required. It improves the production flow efficiency of the business.

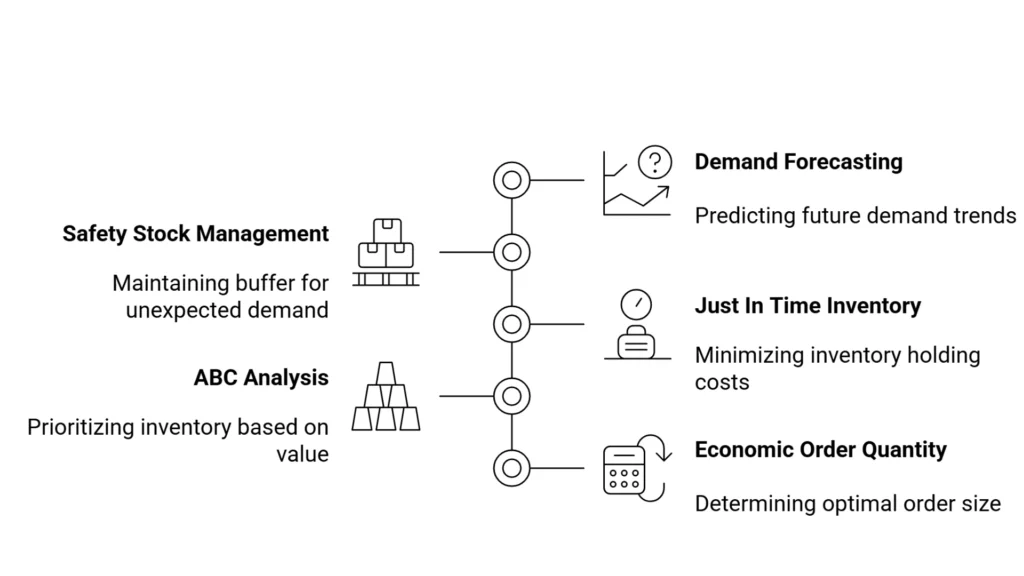

Key Components Of Inventory Optimization

The components of inventory optimization are as follows.

1. Demand Forecasting

A business can use historical sales data, study market trends, and forecast product demand in the market. It will not only improve cash flow but also avoid problems of overstocking and understocking. A business can even use AI and machine learning to forecast product demand more accurately.

2. Safety Stock Management

Safety stock acts as a buffer inventory and prevents stockout problems. A business can utilise safety stock when the product demand spikes suddenly in the market or there are supply chain disruptions. For example, historical demand fluctuations maintain safety stock in the warehouse accordingly.

3. Just In Time Inventory

Just-in-time inventory is a strategy that replenishes stock when necessary in the warehouse. This strategy reduces excess inventory and optimises cash flow in a business. A successful JIT business needs to partner with reliable suppliers and should have efficient logistics so that it can replenish stock when necessary.

4. ABC Analysis

ABC analysis is a method that prioritizes inventories based on value. This analysis will help a business to focus on essential stocks by avoiding overstocking or understocking issues.

ABC analysis works in the following ways.

- Class A Items: These items are highly valuable and require tight monitoring.

- Class B Items: These items are not as valuable as class A items but need regular tracking.

- Class C Items: These items are of high quantities and are not as valuable as Class A or Class B items.

5. Economic Order Quantity

Economic order quantity is a mathematical expression that determines how much quantity a warehouse should order to avoid overstocking or understocking issues.

EOQ = √((2DS) / H)

- D = Annual demand

- S = Ordering cost per order

- H =Holding cost per unit per year

How Inventory Optimization Works: Step-by-Step Process

1. Collect & Analyze Data

Collecting and analyzing data is one of the most crucial steps of inventory optimization. It involves collecting data from historical sales, stock levels, and supplier lead times. The business then cleans, validates, and analyzes them to identify demand patterns, slow-moving products, and bottlenecks.

2. Forecast Demand

Demand Forecasting is a process of estimating product demand using historical sales data and market trends. This process will help a business to predict how many quantities to order and at what time to avoid overstocking or understocking issues.

3. Classify Inventory

The business needs to classify inventory based on its value and demand behavior. For example, a business can use ABC analysis to classify the products in the warehouse. FSN analysis is an even better technique. The company needs to classify products based on fast-moving, slow-moving, and non-moving items.

4. Set Optimal Inventory Levels

Setting optimal inventory levels means keeping the right amount of stock in the warehouse storage facility to meet customer demand without overstocking. A business needs to calculate safety stock based on demand and lead time variability and set minimum and maximum stock limits. Optimal inventory levels improve cash flow and fulfill the demand of customers consistently.

5. Plan Replenishment Cycles

A business needs to set reorder points and determine order quantities by using methods like the economic order quantity. Effective replenishment planning ensures continuous product availability in the warehouse and reduces problems of overstocking and understocking.

6. Optimizing Storage & Warehousing

These steps include keeping inventory in an organized form to maximize space inside the warehouse as much as possible. The warehouse and storage staff should make better use of racks and shelves to keep inventory in an organised manner. It will improve picking speed and enhance the order fulfillment process.

7. Monitor, Adjust, Improve

The business needs to continuously monitor the inventory turnover ratio, carrying costs, and fill rate using real-time data. Constant monitoring will help a company to identify bottlenecks and take action accordingly.

Inventory Optimization Techniques & Methodologies

1. Statistical Techniques

Statistical techniques use traditional methods like moving averages and exponential smoothing for demanding forecasting. It even includes the usage of the mathematical formula of economic order quantity and reorder point to calculate minimum and maximum stock levels.

2. Machine Learning Based Optimization

It includes advanced methods to analyse complex and large data. For example, a business can utilize AI to investigate patterns, seasonality, and external factors. AI and machine learning can optimize buffer stock, replenishment planning, and avoid overstocking issues.

3. Lean Inventory Practices

Lean inventory practices, like the just-in-time method, can avoid problems of overstocking—a business needs to order products from the manufacturer only when it is necessary. The just-in-time inventory method ensures that the product is received only when it is essential for production or sales.

4. Multi-Echelon Inventory Optimization

A business can have inventories in multiple locations, like factories and warehouses, in various regions of India. Multi-Echelon inventory optimization is an advanced inventory planning approach that optimizes stock levels across multiple locations. It treats all the warehouses and factories as one connected network rather than separate warehouses or factories.

Inventory Optimization In Warehousing

1. Smart Slotting & Warehouse Layout Planning

Smart slotting ensures that staff store the product in the most efficient locations for easy picking. For example, the staff places the fast-moving products near picking and dispatch zones.

2. Automation In Inventory Optimization

Automation improves the speed of the order fulfillment process. For example, a business can use advanced software like a warehouse management system to optimize the layout and for real-time inventory tracking. The company can use IOT sensors for tracking inventories.

3. Inventory Counting & Accuracy

It ensures that the physical counting of inventories in the warehouse matches the system. High accuracy is essential for inventory optimization and order fulfillment.

Tools And Technologies That Enable Inventory Optimization

Various tools and technologies enable inventory optimization. They are as follows.

1. Inventory Optimization System

2. Warehouse Management System

3.AI and machine learning

4. RFID & IOT technologies.

Common Inventory Optimisation Mistakes To Avoid

- There are some businesses that depend only on manual inventory tracking. It can lead to errors or planning mistakes. 3PL companies can find it challenging to track stock levels.

- There are some businesses that hold excess inventory because of the fear of understocking issues.

- If a business ignores seasonal demand patterns, then it can result in stockout problems.

- An inefficient warehouse layout can cause handling errors and increase labor and operational costs.

How AAJ SCM Can Improve Inventory Optimization?

- AAJ SCM uses advanced technology, like a warehouse management system, to optimize warehouse layout and track stocks in real time.

- The Company uses historical data and lead time analysis to set optimal inventory levels.

- AAJ SCM offers scalable solutions, i.e, it can accommodate products when the business expands in the future.

Final Words

Inventory optimization is a process of maintaining enough stock levels to balance supply and demand. It is pretty essential for the success of the supply chain as it reduces stockout issues and enables faster order fulfillment. A business can use advanced technologies like AI, machine learning, and a warehouse management system to optimize inventory.