Batch picking is a highly efficient order fulfillment strategy. The picker needs to collect orders of multiple customer orders at a time and bring them to the sorting or packaging station. This method reduces time and boosts order fulfillment efficiency by 30-40% compared to single-order picking. It can handle large fulfillment orders with almost negligible errors, thereby enhancing customer satisfaction.

What Is Batch Picking?

Batch picking is an efficient method of order picking in warehouses and fulfillment centers. Here, the warehouse staff collect items for multiple orders in a single trip through the warehouse. It saves time and helps in completing multiple customer orders quickly.

Modern warehouses are now utilizing advanced technology, including WMS and order management systems (OMS). These software groups identify ordered items or items of the same picking paths in a batch and assign the task to the picker. The picker collects all these items on a single trip through the warehouse.

Batch picking is usually faster than other picking strategies, such as single-order picking. In single-order picking, the warehouse staff picks only one ordered product at a time. Many reports show that in single-order picking, warehouse staff often walk nearly 16 kilometers a day, which is quite stressful and tiring and also slows the order fulfilment process. However, batch picking significantly reduces travel time.

Bath Picking Example

Let's understand this with an example:

- Customer A has ordered the following

- 30 packages of batteries

- 10 units of LED lights

- Customer B's orders are as follows

- 20 packages of batteries

- 5 units of LED lights

- Customer C orders the following

- 2 LED lights

- 10 packages of batteries

In single-order picking, picker 1 must collect items only for customer A and then return to the packaging area. Picker 2 then walks down the same aisle and collects for customer B, and Picker 3 collects items for customer C. There are three trips on the same warehouse aisle, which increases travel time and delays order fulfillment.

But in batch picking, a picker collects all 60 battery packages and puts them in the cart's tote. He collects the 17 items of LED lights in another tote of the cart. The picker brings all these items to the packaging area so they can be prepared for shipping. The picker has collected all the items for customers A, B, and C in a single trip, thereby increasing the efficiency of the fulfillment process.

When Batch Picking Works Best?

- When a large number of customers order the same or a few standard stock-keeping units, batch picking maximizes order fulfillment efficiency.

- It works efficiently when integrated with a warehouse management system.

- It is ideal for picking lightweight items or non-bulky products.

- It is ideal for businesses that want to deliver orders to customers on the same day or the next.

When Is Batch Picking Not Recommended?

Batch picking is not always the most efficient picking and packing solution. Some of them are listed below.

- Single-batch picking requires sorting after picking multiple orders. But if a business does not have adequate space, then it's not ideal for it.

- If the items are too bulky, batch picking is not a suitable option.

- It is not ideal for costly products.

How Batch Picking Differs From Single Order Picking, Wave Picking, And Zone Picking?

| Features | Batch Picking | Single Order Picking | Wave Picking | Zone Picking |

| Definition | Here, the picker collects items for multiple orders at a time. | Here, the picker collects items for a single order at a time. | Here, the advanced software releases a group of orders based on criteria like shipping schedules at a specific time. | Here, the pickers are assigned specific zones. They need to collect the ordered product from the specific zone only. |

| Travel Time | Low | High | It depends on wave size or warehouse layout. | Low |

| Order Fulfillment Efficiency | High | Low | High | High because the picker does not need to travel much. |

Top Benefits Of Batch Picking

Batch picking has various benefits. Here is a list of them below.

- Reduces Picking Time: Batch picking involves collecting multiple orders simultaneously, which reduces the time required for order fulfillment.

- Lowers Labor Costs: A business can handle more orders with the same or fewer workers through batch picking. This reduces the business's labor costs.

- Faster Order Fulfillment: The warehouse picks multiple orders at a time through Batch picking. This speeds up the business's order fulfillment process. A business can deliver ordered products to customers more quickly, thereby enhancing customer satisfaction.

- Requires Congestion: Heavy movement in the warehouse facility can cause accidents. However, in batch picking, a single picker selects multiple order items at a time, which helps reduce congestion and improve safety.

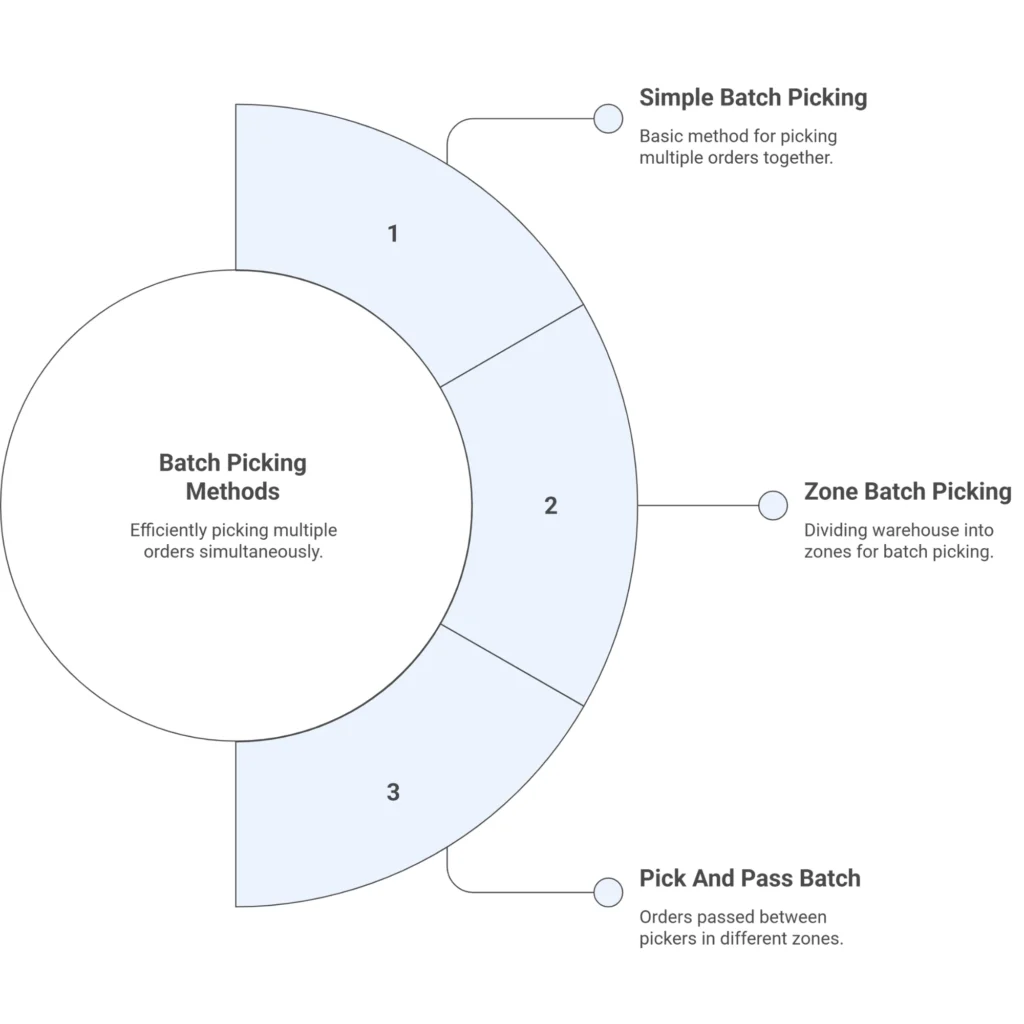

Different Types of Batch Picking Methods And Variants

There are various batch picking methods. Some of them are listed below.

1. Simple Batch Picking

Here, the warehouse management system groups customers' orders with similar items and assigns a picker. The picker collects items of multiple orders at a time and brings them to the sorting area. The items are sorted and packaged appropriately so the 3PL company can hand them over to the shipper. This method is ideal for small to medium 3PL warehouses.

It is a simple, cost-effective method to implement and fulfill orders quickly. But it has a few limitations, like sorting can take a lot of time after picking multiple items.

2. Zone Batch Picking (Hybrid Picking)

It is a combination of both zone and batch picking methods, also called Hybrid Picking. The warehouse is divided into various zones. The warehouse management system assigns pickers to each zone. The picker must select multiple orders from the designated zones and then transport them to the sorting area. It is best for large warehouses. This method reduces congestion in the warehouse and speeds up order fulfillment. But it requires proper sorting after consolidating all the products collected from various zones.

3. Pick And Pass Batch

Here, the picker of each zone picks up products of multiple orders and then passes them to the next zone. The process continues until the last zone, and then all the collected items are sorted by the warehouse staff. This process improves accuracy and reduces errors, as pickers handle products only within their assigned zones of the warehouse. It works well when used with conveyor systems. However, the pick-and-pass batch has a few limitations, such as the need for conveyor systems or automated material handling, which can be expensive for businesses and warehouse companies.

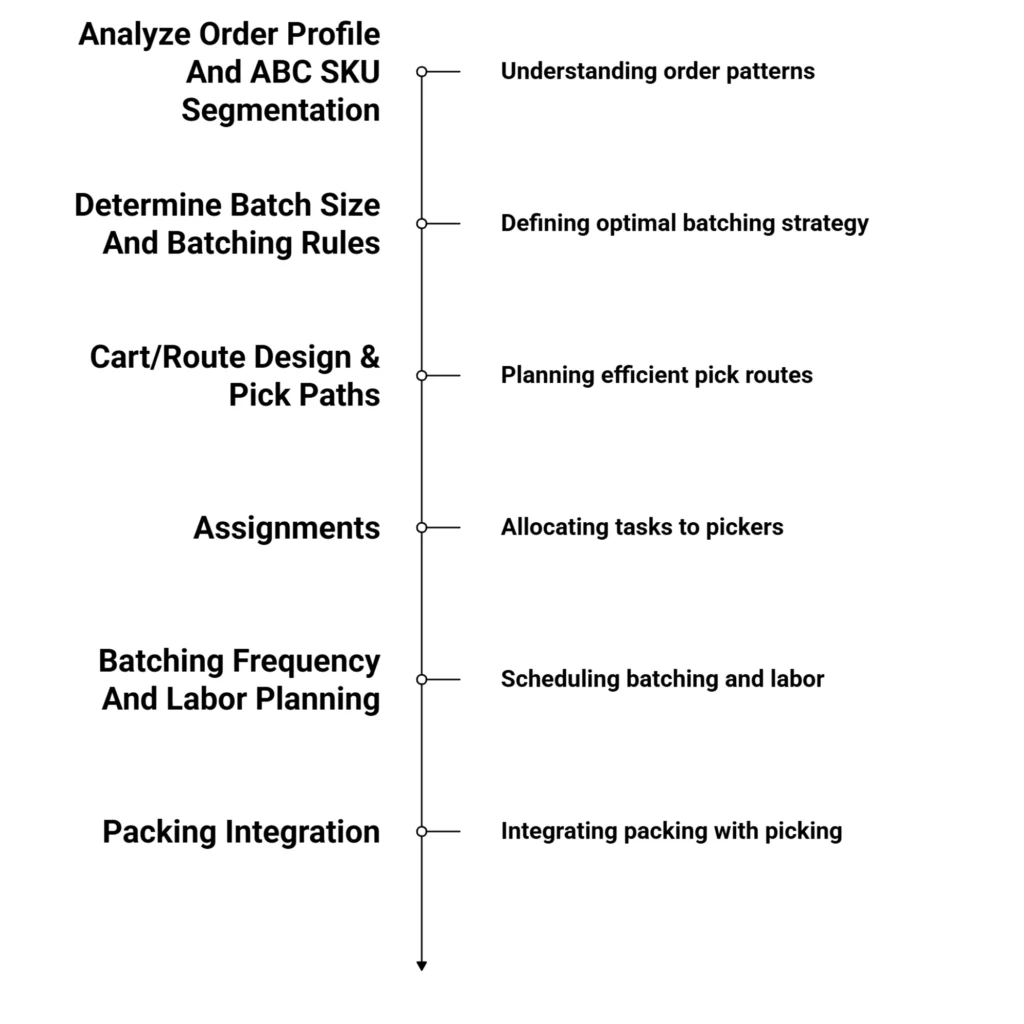

Efficient Batch Picking Process Step By Step

1. Analyze Order Profile And ABC SKU Segmentation)

The business needs to analyze the order patterns and their volumes. It can even perform the ABC analysis, categorizing items into three classes: Class A (highly valuable), Class B (less valuable than Class A), and Class C (less valuable than Class A and Class B).

2. Determine Batch Size And Batching Rules

A business can set the batch size based on the picker's capacity or the cart's space. It can even use advanced technologies, such as WMSs and pick-to-light systems, to automatically group orders.

Pick-to-light system is a warehouse picking technology that uses lights and digital displays to guide workers to the correct items and quantities, making the picking process faster and more accurate.

3. Cart/Route Design & Pick Paths

Batch picking efficiency depends on cart design and travel routes. Pickers can use digital pick lists or scanners to speed up the process.

4. Assignments

Pickers can receive orders based on their zone familiarity or workload. The warehouse, which uses WMS software, groups orders into batches based on factors such as order size and weight, or similar storage zones.

5 . Batching Frequency And Labor Planning

Batching frequency refers to the frequency at which the warehouse creates batches. Some businesses create a fixed batching frequency, while others make it based on the arrival of new orders. Labor planning here refers to forecasting the number of workers who are readily available to pick, package, and deliver goods to the shipper.

6. Packing Integration

The warehouse staff verifies each order correctly on the packing or sorting station. The staff ensure there are no damaged items on the packaging station. They have to verify quantities as per the customer orders.

Common Problems In Batch Picking And How To Fix Them

- Pickers can spend significant time in the aisle searching for products due to an improper warehouse layout. The business should optimize warehouse design accordingly.

- Inefficient batch grouping can increase the time warehouse staff spend walking. Businesses can use a warehouse management system to efficiently create batches.

- Warehouse staff can place products in the wrong bins, leading to order fulfillment errors. The business can use barcode scanning to ensure proper sorting.

How To Implement Batch Picking?

- The business needs to analyze order history, identify paths, and determine the most demanding products in the warehouse.

- The business should start with a single batch and observe the picker's speed and the challenges they face.

- If the business observes that the first batch is successful, then it can expand to multiple shifts.

- The business should continue to review its performance and monitor key metrics, including pick rate and travel time.

Final Words

Picking order items plays a crucial role in the warehouse. A single order picking increases the time required of warehouse staff and delays the shipment of products. However, batch picking is an efficient method that enables a warehouse storage worker to pick orders for multiple customers simultaneously. This reduces travel time and speeds up order fulfillment for a business. However, batch picking is not effective for companies that lack sufficient space for sorting or packaging, or those that deal with bulky products.