Lead time plays a vital role in inventory management and supply chain operations. Research says that a day delay in lead time can cost businesses thousands in lost sales. It even adversely affects the operational efficiencies of the business.

Lead time affects inventory availability, cash flow, and customer satisfaction. A longer lead time can cause delays in order processing and dissatisfied customers. Businesses should implement specific strategies to reduce lead time, such as maintaining good relationships with reliable suppliers and keeping sufficient stock to fulfill customers' orders quickly and efficiently.

What Is Lead Time?

Lead time is the period between ordering and receiving products from the supplier. A shorter lead time can enhance the efficiency of the overall supply chain process. It ensures product availability in the warehouse, which helps with quick delivery to customers. Shorter lead times can increase brand reputation in the market. So, lead time plays a crucial role in the overall supply chain efficiency of the business.

Simultaneously, the organisation can understand the suppliers' lead time of various materials and plan inventories to avoid stockout problems and missed sales opportunities.

Difference Between Lead Time In Inventory Management And Supply Chain

Lead time in inventory management refers to the time taken to order and receive the stock from the business. Longer lead time in inventory management can lead to stockout problems.

Let's discuss lead time in inventory management with an example. A retail store sells kitchen blenders to customers. When the retailer determines the reorder point, he orders the kitchen blender from the seller on 1st April. The seller delivered the blender on April 8th. So the lead time is 7 days.

Lead time in the supply chain operations refers to the time taken from sourcing raw materials to delivering the finished product to the sellers or customers. A delay in supply chain lead time can satisfy customers and decrease brand reputation.

Let's discuss lead time in the supply chain with an example. A Company manufactures bicycles. The process will begin with ordering various raw materials, such as rubber, spokes, and other necessary components. It takes around 10 days for the supplier to deliver the raw materials. Again, the manufacturing will take almost 6 days, and the shipping will take 2 days to reach the customer.

So, the lead time in the supply chain is 10+6+2 = 18 days.

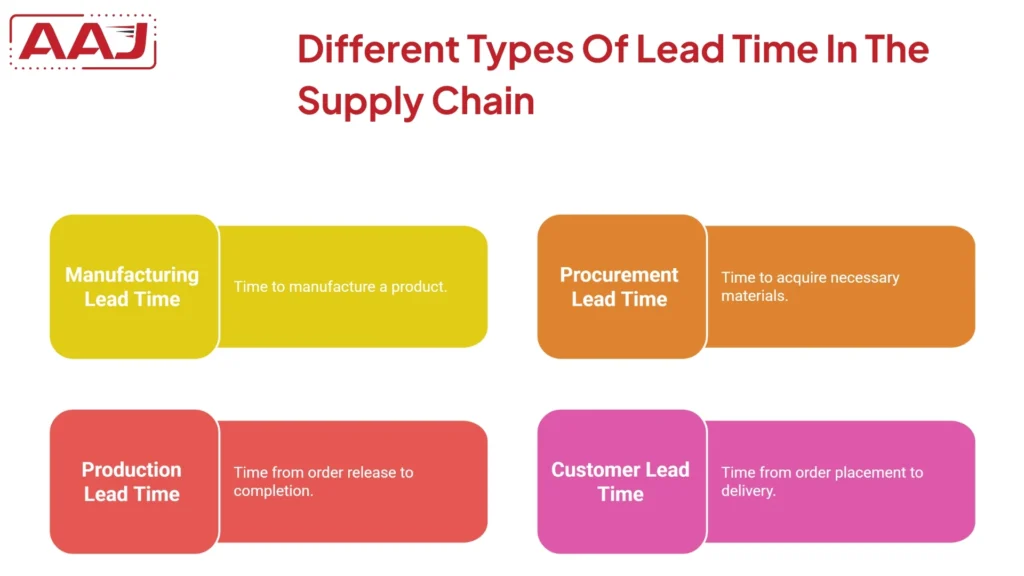

Different Types Of Lead Time In The Supply Chain

1. Manufacturing Lead Time

It is the time from receiving the order to manufacturing and delivering a product to the customer. It includes various stages like sourcing raw materials, assembly, and quality checking.

The manufacturing lead time can vary depending on factors such as order size, product complexity, raw material availability, production steps involved, and other relevant factors.

2. Procurement Lead Time

Procurement lead time refers to the period from ordering to receiving raw materials from the external supplier. Various factors affect the lead time in procurement, like supplier reliability and their geographical position. For example, if the suppliers are located in distant areas, then products can be delayed. Again, if the suppliers face specific problems or lack much expertise, they can cause issues providing goods to the business.

3. Production Lead Time

Production lead time is the total time taken for manufacturing a product once all the raw materials are available. The lead time can be several weeks or months, depending on the complexity of the product. Faster production, i.e., when the production lead time is shorter, enables the company to deliver products quickly to customers.

4. Customer Lead Time

Customer lead time is the total time from ordering a product to delivery. There are various stages of customer lead time.

- Order Placement: The customer places an order on the e-commerce website.

- Order Processing: The customer verifies the order and payment details, then sends them to the warehouse.

- Picking And Packing: The warehouse staff picks up the ordered product from the shelf, does a thorough packaging, and ships it to the customer.

Shorter lead time can enhance customer satisfaction and improve brand reputation in the market.

Cycle Time Vs Lead Time

Both cycle time and lead time are important aspects of the logistics operations. Lead time encompasses right from order placement to delivery. But cycle time is the time required to complete one logistics process.

However, shorter cycle times and lead times can improve a business's order processing and delivery processes. It enables a business to meet customer expectations readily.

How To Calculate Lead Time?

The formula for lead time is as follows.

Lead time = Order delivery date - Order request date

This formula measures the time from order placement to delivery of goods or products.

Let's discuss a few examples

1. Inventory Restocking

A retail store ordered 700 shampoos from the seller on 8th March. The suppliers deliver the order on 16th March.

So the total lead time = 16th March - 8th March = 8 days.

2. Manufacturing Lead Time

Manufacturing Lead time = Procurement time + Production time + Shipping time

For example, a company produces wooden tables.

Procurement time for wood and other materials = 8 days.

Production time = 5 days.

Shipping time = 3 days

So lead time = 8+5+3 =16 days

3. E-commerce Fulfillment

A customer orders a pair of sneakers on 10th September.

The order processing will take almost 1 day.

The packaging time for the sneaker pairs is 1 day.

The shipping or delivery of the sneaker will take 5 days.

So the total lead time here is 7 days.

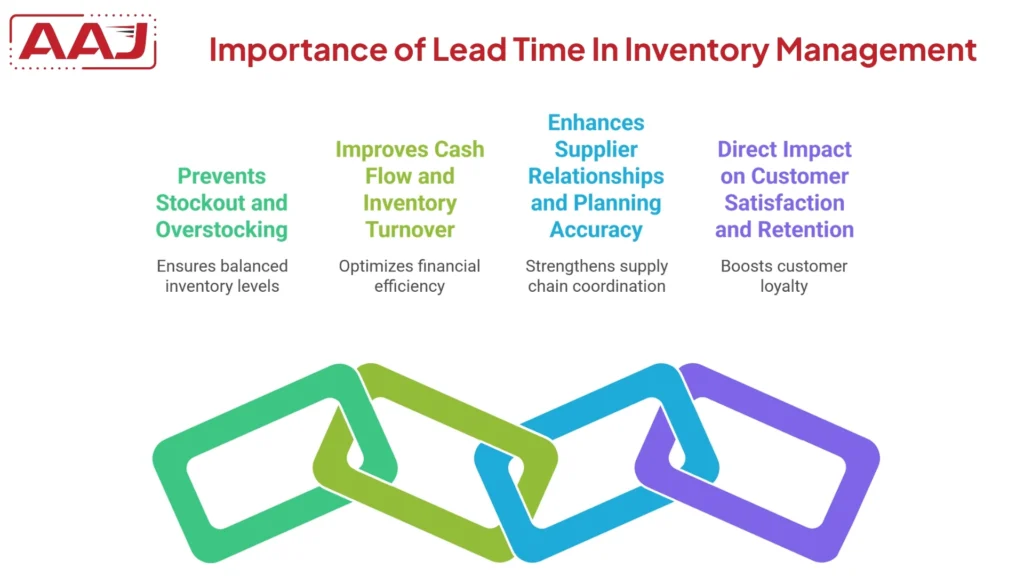

Importance of Lead Time In Inventory Management

1. Prevents Stockout And Overstocking

When a business knows the accurate lead time, it can calculate the reorder time and order products from the seller accordingly. This helps a company to prevent problems like overstocking and out-of-stock issues.

2. Improves Cash Flow And Inventory Turnover

Shorter lead times enable businesses to maintain low stock levels in the warehouse and order as needed. It even frees up working capital, allowing companies to allocate it to other key initiatives, such as designing a new product.

A shorter lead time even improves the inventory turnover rate of the business. It means products start moving faster to their destination, improving the overall supply chain efficiency.

3. Enhances Supplier Relationships And Planning Accuracy

Tracking lead time allows a business to identify reliable suppliers in the market. It can even plan orders more accurately and deliver faster to the customers.

4. Direct Impact On Customer Satisfaction And Retention

Shorter lead times enable businesses to deliver products to customers quickly, thereby enhancing customer satisfaction.

Factors That Affecting Lead Time

Various factors affect the lead time. Here is a list of them below.

1. Supplier Location

Local suppliers will deliver products faster to the business. However, international suppliers will take longer to transport products due to their shipping and logistics times. Again, they may face logistics challenges during transportation, which can cause a delay in lead time.

2. Supplier Reliability And Response Time

A business can deliver orders efficiently and on time if it chooses reliable suppliers. Unreliable suppliers can cause delays in delivering goods due to miscommunication or production problems.

3. Custom & Import/Export Regulations

Custom clearance plays a vital role in affecting lead time, especially when goods cross an International border. There can be a delay in lead time because of incorrect paperwork or new rules and regulations. Authorities can take time to inspect the product, especially for restricted goods.

4. Manufacturing Capacity

Here, manufacturing capacity means the maximum output a production Company can provide within a particular period. Machinery breakdown or a lack of special equipment can delay the manufacturing of a specific product and cause a longer lead time. There are other factors too, like a lack of labour or large complex orders, which can delay the manufacturing process and cause longer lead times.

5. Internal Process Delays

Data entry errors or miscommunication between departments can cause delays in placing orders with the supplier. This can cause stockout problems and dissatisfy customers.

How To Reduce Lead Time?

A business can reduce lead time in the following ways.

- It should maintain a good relationship with the reliable suppliers. Effective communication through emails, calls, and ERP can reduce misunderstandings. It ensures the delivery of products in the correct order to reduce lead time.

- The business should source raw materials or finished products from the local suppliers. This reduces transit time and leads to a short lead time.

- The business can maintain safety stock in the warehouse, particularly when supplier lead times are unpredictable.

Common Mistakes Businesses Make With Lead Time

1. Relying On A Single Supplier

When a business depends on a single supplier, there can be delays or disruptions in warehousing and transportation. It can lead to longer lead times and stockout problems in business.

2. Not Accounting For Seasonal Delays

Businesses usually overlook the impact of holidays or weather disruptions on product delivery. The supplier can become overwhelmed, particularly during a demand spike in a specific season or holiday, which can lead to delays in product delivery.

3. Poor Communication With Vendors

Most businesses do not adequately communicate with the vendors, leading to production errors and shipping delays.

Final Words

Traditionally, companies used to generate lead time by studying historical data and market trends. But now most e-commerce companies use advanced technology like AI and simulations to predict lead time. They maintain good relationships with suppliers, which helps them achieve shorter lead times.