Inventory control involves a process where 3PL and businesses manage and regulate stock levels to make sure that the right quantity of products is available at the right time.

According to a report, more than 60% of India's business owners rely on manual or semi-automated inventory systems, which increases warehousing and holding costs. To reduce this cost, Inventory control is important for businesses.

Inventory control is an integral part of supply chain and warehouse management. It ensures that a business needs to have optimal inventories in the warehouse to meet customer demands. It involves tracking and managing inventories in the warehouse to reduce wastage and prevent stock issues.

What Is Inventory Control?

Inventory control involves managing and maintaining a business's stock levels to meet customer demands. Its main objective is to reduce the holding costs as much as possible.

Most people think that inventory control and inventory management are similar terms. But in reality, they are both different. Inventory control refers to keeping and maintaining stock once it is in a warehouse facility. Inventory management encompasses broader tasks, which include ordering, tracking, and selling inventories. The inventories can be raw materials or finished goods.

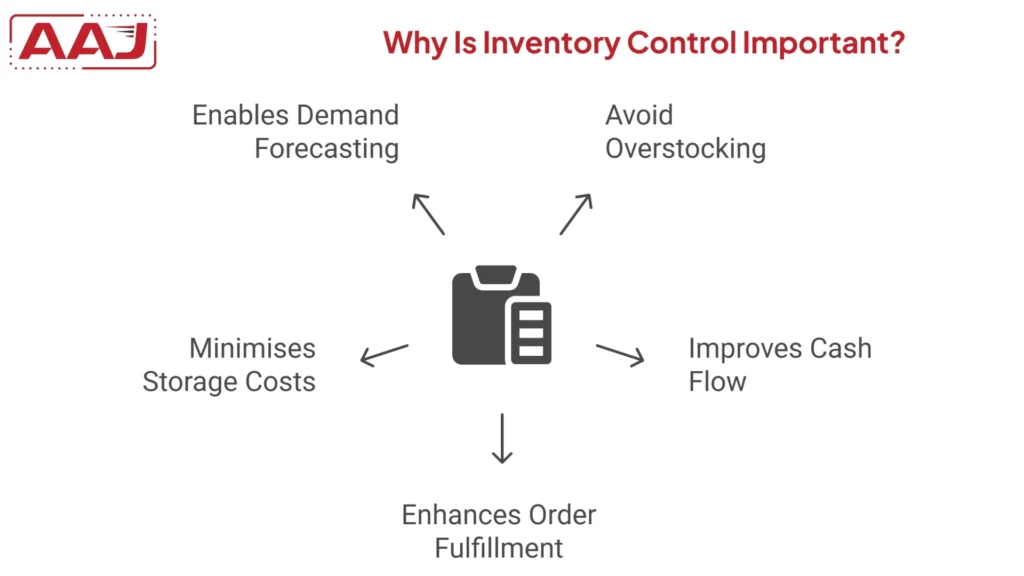

Why Is Inventory Control Important?

Inventory control plays an integral part in the business supply chain. Its importance is listed below.

1. Avoid Overstocking And Understocking

Overstocking products inside the warehouse can lead to damage to various products. It even increases the storage costs of the business. Again, understocking can cause a negative impression on customers. Effective inventory control avoids overstocking and understocking issues in the company.

2. Improves Cash Flow And Working Capital

Inventory is one of the most significant assets on the business's balance sheet. However, liquidity and sales are reduced if the business overstocks products. Effective inventory control frees up working capital so the company can utilize it in core operations like product development.

3. Enhances Order Fulfillment Rates

Proper inventory control fulfills orders faster and increases customer satisfaction, even increasing brand reputation.

4. Minimizes Storage Costs And Shrinkage

Excess inventory requires additional space in the warehouse, increasing storage costs. Again, unmanaged stock can lead to damage or be susceptible to theft. Proper inventory control reduces these risks and ensures an appropriate amount of products are always available to meet customer demands.

5. Enabling Demand Forecasting And Planning

Proper inventory control forecasts product demand effectively and allows for better planning.

Types Of Inventory In Inventory Control

Different types of inventory in inventory control are as follows.

- Raw Materials: They are required to produce finished goods.

- Work In Progress: These inventories are still part of the production process.

- Finished Goods: The production process is already complete in these inventories, and they are ready for sale.

- Maintenance, Repair, and Operations (MRO) Inventory: These inventories support the production process but are not part of the finished goods, for example, oil and lubricants.

Each of these inventories serves a different purpose in the supply chain. Mismanagement of any inventory can lead to increased storage costs or a delay in the production process. For example, if we talk about raw materials, the business should replenish them on time so that the production process does not hamper.

Objectives Of Inventory Control

Inventory control is an integral part of the supply chain process. The objectives of inventory control are as follows.

- Optimizes Stock Level: Inventory control optimises stock levels by avoiding overstocking and understocking issues.

- Ensure Smooth Production Flow: It ensures that raw materials are available when required to avoid an uninterrupted production process.

- Minimise Carrying Costs and Deadstock: Proper stock control reduces the holding costs of the business.

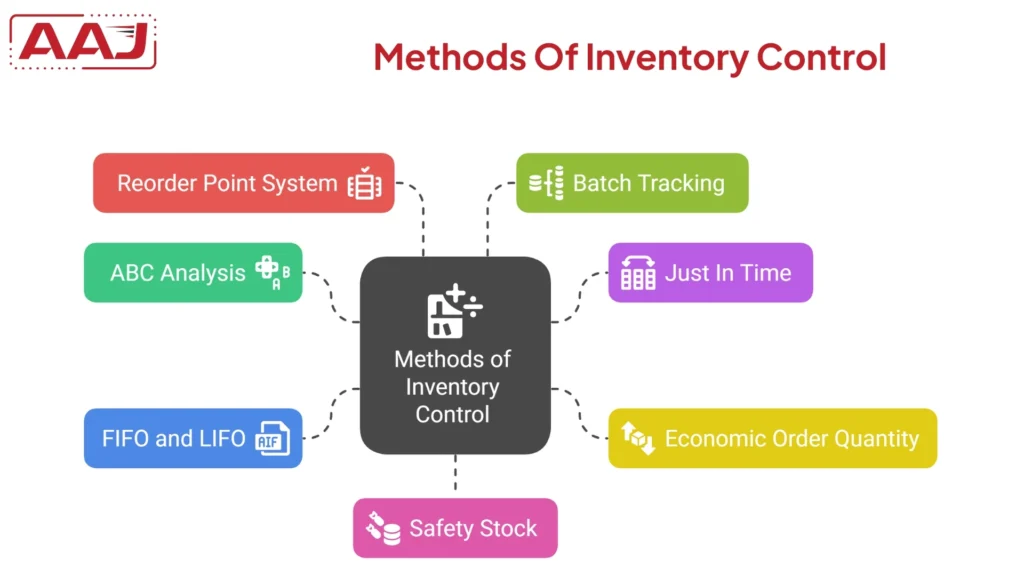

Methods Of Inventory Control

There are various methods of inventory control. Here is a list of them below.

1. ABC Analysis

ABC analysis classifies inventory into three groups.

Class A: They are expensive and highly valuable inventories. They require close monitoring and regular review to avoid stock-out problems.

Class B: The inventories in Class B are essential but not as important as Class A. Businesses need to balance Class B inventories to ensure smooth operations.

Class C: They represent a larger portion of the inventories and are not very valuable. Businesses should even manage these inventories efficiently to avoid unnecessary storage costs.

2. Just In Time

It is an inventory management strategy where the business orders products only when required. Just-in-time inventory concept reduces unnecessary storage costs for the business, delivers good service on time, and increases customer satisfaction.

However, there are some drawbacks to JIT management. For example, supply chain disruptions like natural disasters or strikes can obstruct the transportation of the required products and adversely affect business operations.

3. Economic Order Quantity

Economic order quantity is a mathematical formula that determines the optimal order quantity for a business to reduce holding and ordering costs. It also manages cash flow. It prevents overstocking and out-of-stock issues.

EOQ = 2DSH

D = Annual demand per year.

S =Ordering cost per order

H = Holding cost per unit per year.

However, this formula is not suitable for perishable products. You need accurate data to determine the business's order quantity, which is quite challenging.

4. FIFO and LIFO

The first in, first out principle states that the oldest inventories are sold out first to the customer. This principle is ideal for perishable goods. It prevents inventories from getting outdated or spoiled.

The last in, first out inventory principle states that the newer inventories are sold out first to the customer.

5. Reorder Point System

It is the inventory management system used to determine when businesses need to reorder the stock.

The formula for the reorder point system is as follows

Reorder system = (Lead time(in days) Average daily usage ) + Safety Stock

6. Batch Tracking

Batch tracking is known as lot tracking. It involves grouping items with the same production characteristics, like expiry dates, manufacturing dates, and location.

7. Safety Stock

Safety stock is the inventory that the business keeps in its warehouse and utilizes when the actual demand exceeds the forecast demand or when the supplier delays delivering raw materials.

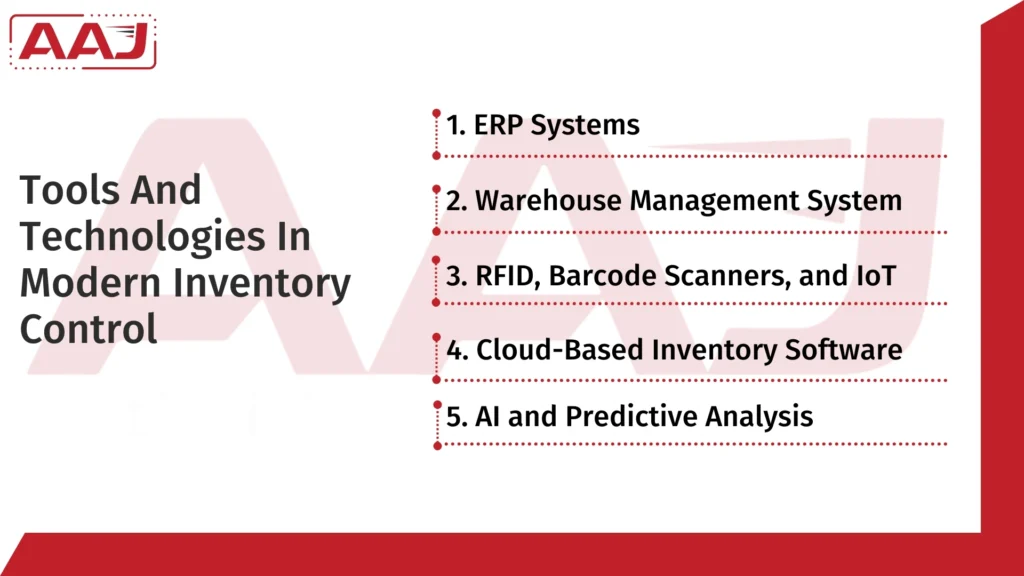

Tools And Technologies In Modern Inventory Control

Modern inventory control uses tools and technologies to improve the efficiency of the business. Here is a list of specific tools and technologies.

- ERP Systems: It is a software system with all the tools required to run a business, including supply chain, finance, and accounting.

- Warehouse Management System: It optimizes the layout of the warehouse and tracks inventories.

- RFID, Barcode Scanners, and IoT Devices: IoT devices can monitor the temperature and humidity of the products in real time. RFID and barcode scanning are used for inventory tracking.

- Cloud-Based Inventory Software: It is a modern solution where business owners can track and manage inventory through internet-connected devices.

- AI and Predictive Analysis: AI and predictive analysis forecast product demand accurately.

Challenges In Inventory Control

Businesses face particular challenges in effective inventory control. Here is a list of them below.

- Inaccurate Data and Human Error: Counting inventories or maintaining records manually can be prone to errors.

- Demand Unpredictability: Improper forecasting of product demand can lead to overstocking and out-of-stock issues.

- Managing a Multilocation Warehouse: Managing multilocation warehouses and real-time tracking inventories is tricky for many small and medium enterprises.

- Obsolete or Slow-Moving Stock: If the stock remains in the warehouse for a longer time, it can get damaged or outdated with time.

- Supply Chain Disruptions: Strikes or natural calamities can delay the flow of inventory, resulting in lost sales and dissatisfied customers.

Best Practices For Effective Inventory Control

1. Regular Audits And Cycle Counts

Regular audits and cycle counts can maintain inventory accuracy in the warehouse storage. Inventory audit involves physical verification of all the inventories kept in the warehouse, quarterly or annually, to identify damaged or outdated products. Cycle counts involve counting specific inventories weekly or monthly.

2. Real-Time Inventory Tracking

Businesses should utilize RFID tags, barcode systems, or cloud-based software to track inventories in real time, thereby avoiding overstocking and understocking issues.

3. Strong Supplier Relationships

Building strong supplier relationships is highly important in inventory control. Reliable suppliers ensure timely deliveries and constant quality during supply chain disruptions.

4. Inventory Segmentation And Classification

Inventory segmentation involves dividing the stock based on various criteria, such as demand and value. Some inventory classification methods include ABC analysis and FSN (fast, slow, and non-moving) analysis.

5. Training Teams And Automating Processes

Businesses need to train teams within the company regarding the warehouse automation process.

Final Words

Inventory control has become a necessity for Indian business owners. It aims to reduce costs, improve supply chain efficiency, and enhance customer satisfaction. There are various inventory control strategies like ABC analysis, just-in-time, and many more. You can adopt them and invest in modern technologies for inventory control.