Warehouse layout plays a vital role in supply chain efficiency. It involves the proper placement of shelves, racks, and material-handling equipment in the warehouse. A well-designed layout ensures products move seamlessly from receiving to dispatch and enhances order fulfillment. This increases the speed of daily operations, reduces picking errors, and helps teams work more efficiently. It also improves space utilization, which means you can store more inventory without expanding the warehouse. It even reduces warehouse workers' travel time and increases picking efficiency. A well-designed warehouse layout even enhances worker safety.

What Is a Warehouse Layout?

Warehouse layout refers to the proper arrangement of equipment and storage zones to maximise space inside the warehouse. There are multiple zones in a warehouse layout, such as receiving, picking, packaging, order preparation, and dispatch. A good warehouse layout ensures that goods are stored and move efficiently from one zone to another. Simultaneously, it reduces product losses and unnecessary accidents and improves the order fulfillment process.

Core Elements Of Warehouse Layout

The core elements of warehouse layout are as follows.

1. Receiving And Staging Zones

The receiving zone of the warehouse focuses on receiving goods from suppliers or manufacturers. The warehouse storage facility staff thoroughly inspects all goods and products to ensure they are not damaged, then places them in the staging zone. The warehouse staff temporarily place the products in the staging zone and then move them to the storage zone.

2. Storage Areas

The storage area is the central zone in the warehouse. Here, the warehouse staff stores the inventory in an organized manner. There are various types of storage areas, like pallet racking systems and shelving units.

3. Picking & Packaging

The picking and packaging zone is the primary area for order fulfillment. Picking zone focuses on choosing the ordered product quickly and efficiently. It can be of various types like zone picking, batch picking and wave picking. These zones reduce travel time and enhance the order fulfillment process. The packaging zone focuses on packaging and labelling the ordered product and preparing for dispatch.

4. Dispatch Zone

Here, the warehouse staff groups packed orders based on the destination or delivery route. The orders are then moved to the loading trucks for B2B transportation purposes.

5. Aisle And Pathways

Aisle and pathways are routes in the warehouse that allow easy movement of heavy machines, such as forklifts and pallet jacks. Workers can even move freely without any obstruction. Clearly marked warehouses reduce accidents.

6. Dock Doors

Dock doors serve as entry and exit points for inbound and outbound goods. They are usually located near the receiving and dispatch zones to ensure a smooth flow in and out of the warehouse.

7. Workstations

There are areas where specific warehouse operations take place, such as kitting, bundling, or return processing.

Warehouse Layout Vs Warehouse Design

Table

Importance Of Warehouse Layout

Warehouse layout is quite essential for the following reasons.

1. Higher Space Utilisation

A proper warehouse layout makes better use of space inside the warehouse. For example, a vertical warehouse storage solution allows more products to be stored in the same area.

2. Faster Picking & Order Fulfillment

Clear pathways and designated zones in the warehouse allow faster picking of order products and packaging. Thai improves the order fulfillment process and enhances customer satisfaction with the business.

3. Fewer Operational Errors

A structured layout reduces confusion and reduces the risk of picking the wrong products from the picking zones. It even ensures that goods move smoothly in and out of the warehouse.

4. Improves Safety & Compliance

Proper aisle widths and clear markings increase safety in the warehouse.

5. Reduces Travel Time

A proper warehouse layout reduces staff travel time during product picking.

6. Better Scalability For Future Growth

A flexible warehouse layout allows easy adjustment of racks or rearrangement of pathways to accommodate more goods in the future.

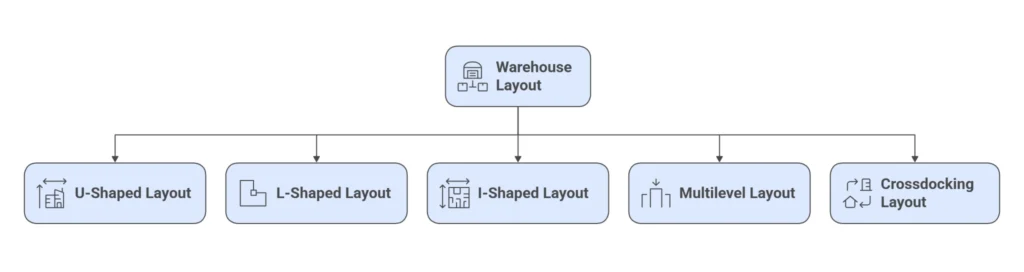

Types Of Warehouse Layout

There are various types of warehouse layouts. Some of them are in the list below.

1. U-Shaped Warehouse Layout

The U-shaped layout is quite popular and is seen in most warehouses. Here, the receiving and shipping zones are placed next to each other. The storage and picking zones are located in the middle and, together, form a U shape. It is best for businesses with medium to high turnover per year.

Pros

- Reduces the travel time of workers.

- Supervisors can easily monitor both inbound and outbound activities.

- The receiving and shipping zones of the warehouse can share equipment with each other.

Cons

- Material flow is not as streamlined as a straight layout.

- The receiving and shipping areas can be challenging for workers to manage during peak hours.

2. L-Shaped Warehouse Layout

Here, the receiving and shipping zones are perpendicular to each other, forming an L shape. The receiving and shipping zones are far apart. So workers do not feel it is challenging to manage during peak hours in a U-shaped layout. The storage and picking zones are there on the inner side of the L. Warehouses with irregular land shapes often adopt this design.

Pros

- Minimises cross traffic.

- Adaptable for different warehouse operations.

Cons

- It can create inefficient picking paths if the warehouse is not designed properly.

3. I-Shaped Warehouse Layout

The I-shaped warehouse layout is also known as the straight warehouse layout. Here, the receiving and shipping zones are located on opposite sides of the warehouse layout. The receiving, storage, and picking zones flow linearly between the receiving and shipping zones.

Pros

- The inbound and outbound zones are separate. It reduces congestion inside the warehouse.

- Streamlines order fulfillment operations.

Cons

- Limited flexibility if the warehouse handles returns frequently.

4. Multilevel Layout

Here, an additional tier is added above the ground floor to maximise the warehouse's vertical space. The extra space is sufficient for picking, packaging, and shipping. Warehouses with high ceilings or ecommerce fulfillment centres can benefit from multilevel warehouses to enhance order fulfillment.

Pros

- Cost effective

- Flexible and modular

Cons

- Initial setup is relatively high

- There is a necessity for conveyors or lifts for material handling.

5. Crossdocking Layout

Here, the goods move directly from the receiving zone to the shipping zone with minimal or no storage in between. It is best for perishable and pharmaceutical products.

Pros

- Lowers storage costs

- Enhances supply chain efficiency.

Cons

- Not ideal for slow-moving products.

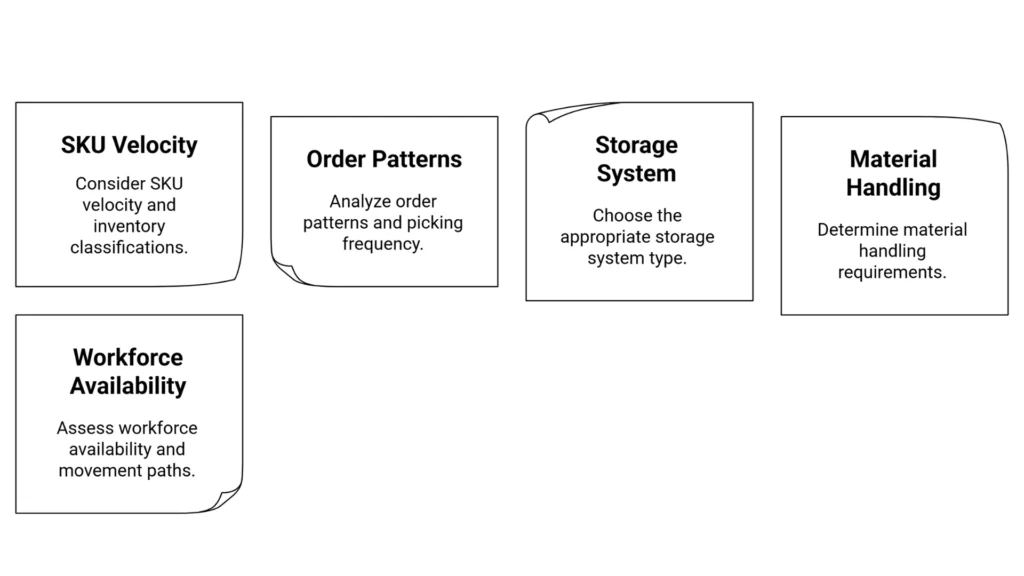

Key Factors To Consider When Designing Warehouse Layout

There are various factors that a business needs to consider while designing a warehouse layout.

1. SKU Velocity And Inventory Classifications

The business should understand SKU velocity, i.e., how fast each product moves in and out of the warehouse. Simultaneously, warehouse companies can combine it with ABC analysis to strategically position the product in the appropriate locations. ABC analysis means grouping the products based on their Value.

2. Order Patterns And Picking Frequency

The business should understand the order patterns and their picking frequency while designing the warehouse layout. The business needs to place the high-demand products close to the picking zones to reduce travel time and speed up order fulfillment.

3. Storage System Type

Choosing the right storage system is quite crucial while designing the warehouse layout. There are various types of storage systems, like pallet racking systems. It is ideal for storing high-volume goods. If a business wants to utilize the vertical space and store bulky or high-volume products, then it should choose a pallet racking system. A business can choose shelving units if it deals with small items.

4. Material Handling Requirements

There are various types of material handling equipment, such as forklifts, conveyors, pallet jacks, and automated guided vehicles. Choosing the right material handling equipment determines the turning radius, aisle width, and rack height in the warehouse layout.

5. Workforce Availability And Movement Paths

Workforce availability and movement paths even play an essential role in designing warehouse layout. The business should design the warehouse layout so workers can move smoothly between zones.

Warehouse Layout Planning Process

- Identify the purpose of the warehouse, the inventory type, the order volume, and specialized services such as kitting and bundling.

- Analyze SKU velocity, size, weight and demand patterns to find the storage needs of a business.

- Outline the complete journey of goods movements, i.e., from their entry to the exit from the warehouse.

- Allocate specific areas for picking, packing, dispatch and shipping based on product demand.

- Choose storage systems and material-handling equipment based on the product type.

- A business can choose CAD tools or other software to design the entire warehouse layout.

- A business can run various simulation tests before implementation.

- Design the layout and monitor warehouse performance.

Common Mistakes To Avoid In Warehouse Layout Planning

- Many businesses place products randomly in the warehouse, which can delay order fulfilment.

- Narrow aisles in warehouses restrict the movement of both workers and equipment. The aisle width of the warehouse depends on the usage of material handling equipment.

- If the business designs the warehouse layout based on current inventory needs, it can lead to space shortages in the future. A business should design the warehouse layout so that racks and shelves can be added in the future.

- If the business places the receiving and shipping zones very close to each other, it can create congestion or delay product delivery.

- If a business chooses the wrong racking systems, then it reduces space efficiency.

Role Of Technology In Warehouse Layout Optimization

Technology plays a vital role in designing innovative and efficient warehouse layouts. A business can use tools such as warehouse management systems, RFID tracking, and barcode systems to track SKU velocity and monitor inventory movement.

Final Words

A well-designed warehouse layout enhances the business's supply chain efficiency. It even reduces operational errors and improves the order fulfillment process. There are various types of warehouse layouts, such as I-type, U-type, multilevel, and more. Each layout type has pros and cons. Businesses can choose the right layout type and enhance operational efficiency.