The material inward process plays a vital role in the supply chain efficiency. However, there can be errors, especially when the business maintains records manually. Again, defective items can arrive in the warehouse because of mishandling or improper packaging. Businesses should move from paper records to digital records to maintain inventory details. It should leverage advanced technology like a warehouse management system for real-time updates regarding inventories or managing warehouse layout.

What is the Material Inward Process?

The material inward process refers to the procedure by which goods and materials enter the warehouse for storage and fulfillment.

The goods and products from the manufacturer or seller arrive at the warehouse facility. The warehouse staff thoroughly inspects and verifies the goods to ensure no defective items are present. They inspect the quality and quantity of the products and update them in the warehouse management system.

Difference Between Material Inward, Material Receipt, And Goods Receiving

Material Inward Process: A process by which a product enters the warehouse facility.

Material Receipt: Receipt confirmation regarding the receipt of products.

Goods Receiving: It is a process of unloading and inspecting products before they enter the warehouse facility.

Role Of Inbound Logistics And Warehouse Management System

Inbound logistics is an essential component of the supply chain. There are some key components of inbound logistics, like:

- Sourcing: It involves the identification and selection of reliable suppliers.

- Transportation: It requires the transportation of goods or products from the suppliers to the warehouse storage.

- Warehouse Facility: It involves goods storage inside the warehouse till the customer orders them.

- Warehouse Management System: A warehouse management system is software that provides real-time inventory updates and avoids overstocking and out-of-stock issues.

Key Objectives Of The Inward Process

The key objectives of the inward process are as follows.

1. Inventory Validation

Inventory validation is a process of verification of the materials received with the purchase order.

2. Quality Assurance

The warehouse team checks the quality of the product thoroughly and ensures that it meets the required standards.

3. Accurate Documentation

The team properly documents all incoming materials inside the warehouse facility.

4. Efficient Put Away Preparation

The team carefully places all the products or materials in the designated places inside the warehouse.

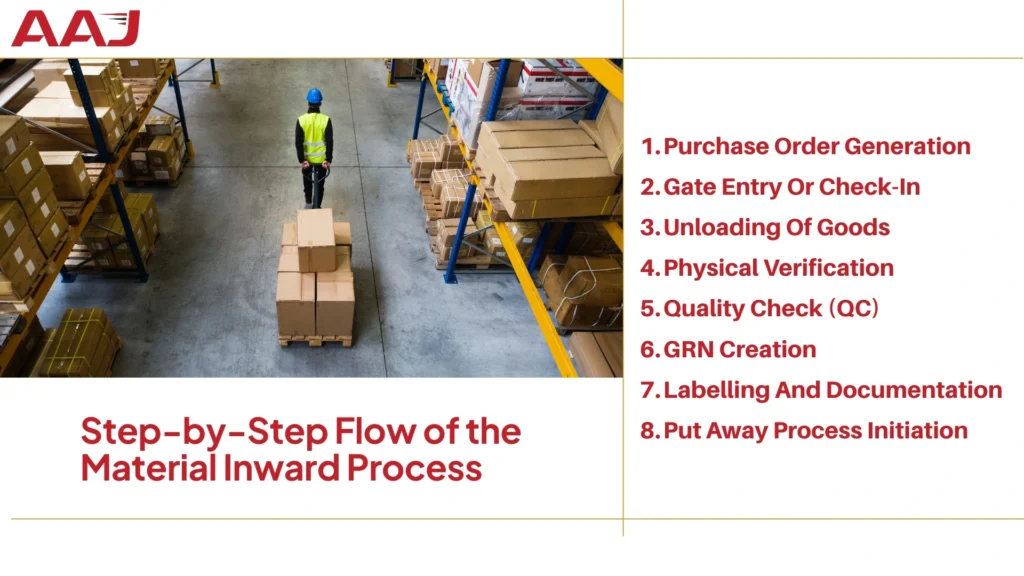

Step-by-Step Flow of the Material Inward Process

1. Purchase Order Generation

The warehouse team sends the purchase order document to the supplier.

2. Gate Entry Or Check-In At Receiving Dock

The supplier vehicles arrive at the dock of the warehouse facility. It enters all the necessary details at the dock area of the warehouse.

3. Unloading Of Goods

The staff of the transport vehicle unloads the goods from the vehicle for proper inspection.

4. Physical Verification And Inspection

The staff verifies each of the materials or products thoroughly. The warehouse staff checks the quantity, packaging condition, and documentation.

5. Quality Check (QC)

The staff inspects the quality of the product to ensure there are no defects or damage.

6. GRN (Goods Receipt Number) Creation

When the staff verifies the quality of the product, a GRN number is created.

7. Labelling And Documentation

The staff labels the product with a barcode or batch code.

8. Put Away Process Initiation

The warehouse management system assigns products to their designated locations inside the warehouse.

Stakeholders Involved In The Inward Process

- Warehouse Manager

- Receiving Team

- Quality Control Team

- Inventory Control Team

- Transporter

Common Challenges In The Inward Process

There are a few challenges in the inward process. Here is a list of them below.

1. Mismatch Between PO And Received Goods

There can be a mismatch between the purchasing order and received items regarding quality, quantity, or specifications.

2. Damage Or Defective Items

Damaged or defective goods can arrive in the warehouse or fulfillment center because of improper packaging or mishandling during transit.

3. Manual Entry Errors

Humans can make errors while entering information about the arrival of products in the warehouse and inventory management system software. It can lead to incorrect inventory records.

4. Delay In Put Away Leading To Staging Congestion

The inventories can be kept in the staging area for a longer time because of the inadequate space in the warehouse.

Best Practices For Efficient Material Inward Process

A business can implement a few efficient material inward processes listed below.

- Schedule deliveries of products only when the warehouse has enough space or dock space is available.

- The warehouse team should maintain records digitally to reduce errors.

- The business should train staff on receiving products, inspecting them, labelling and putting them inside the warehouse and logistics hub.

- The business should use a live dashboard to monitor each inward process stage.

Final words

Material inward process is a process of receiving goods in the warehouse facility. The staff inspects each of the products and checks its quality. They then maintain the record in advanced software like a warehouse management system and place them inside the warehouse.