Inventory Forecasting is the method where businesses predict the product demand in future by analyzing the past sales data and market research.

Inventory forecasting has become essential for the success of any business. Stats show inaccurate forecasting can lead to 10%–20% of lost sales due to stock-outs or mis-stocking. Forecasting helps a business maintain optimal stock levels in the warehouse and avoid missed sales opportunities or high holding costs. There are various ways a company can forecast product demand, including qualitative and quantitative methods. Here are various cloud-based software solutions that can analyze warehouses and display stock availability in a single dashboard. Businesses can utilize such processes and tools to stand out in this competitive market.

What Is Inventory Forecasting?

Inventory forecasting is a process of forecasting product demand in the market. A business combines sales data with market research to estimate how much product to hold in stock for a given time frame to avoid understocking.

Why Inventory Forecasting Matters?

- Overstocking can increase the business's holding costs, and understocking can decrease customer satisfaction. Inventory forecasting ensures there is sufficient inventory to meet customer demands. It avoids the business's understocking and overstocking issues.

- Proper inventory forecasting helps suppliers, manufacturers, and logistics partners to plan production or delivery efficiently.

- Optimal inventory levels reduce the risk of obsolescence in the warehouse.

Different Types of Inventory Forecasting Methods With Formula

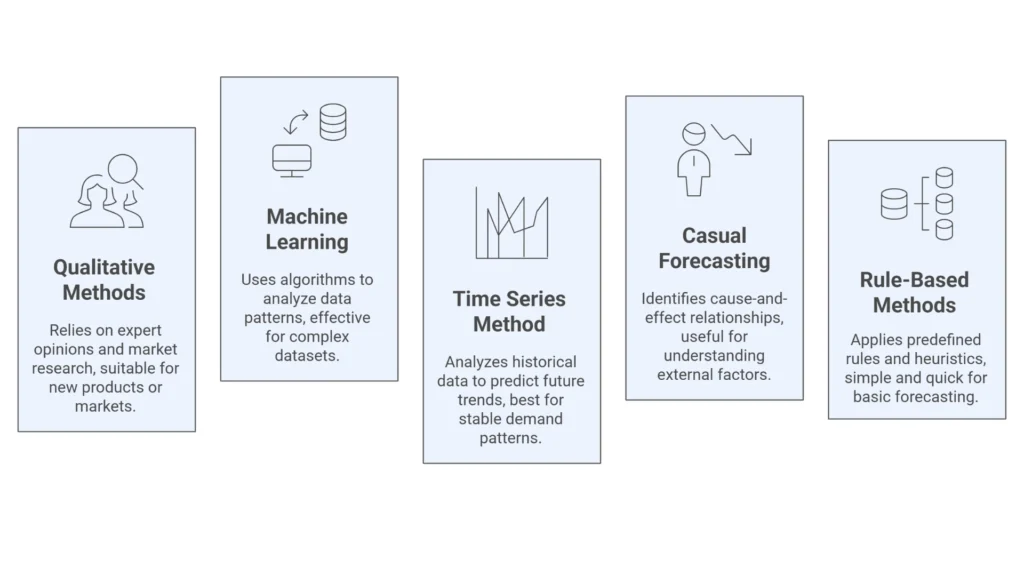

There are various types of inventory forecasting methods. Here is a list of them below.

1. Qualitative Methods

Here, the business depends on market expert opinions or market research to predict product demand. Let's discuss the market research forecasting technique. The business applies this technique especially when launching a new product in a specific geographical area. It collects the data by interviewing the customers and then makes decisions.

2. Machine Learning And Hybrid Models

The traditional forecasting method uses fixed equations or assumptions to predict future market product demand. But machine learning and hybrid models use advanced algorithms for analyzing large amounts of data.

3. Time Series Method

The time series method uses past sales data to predict product demand in the near future. There are various time series methods, such as the moving average, exponential smoothing, and weighted average methods.

Let's discuss the moving average method. It is a simple time-series forecasting method. Here, you need to use past sales data to calculate the average and predict product demand in the market.

Formula Ft⁺¹ = (Dt + Dt⁻¹ + Dt⁻² + … + Dt⁻ⁿ⁺¹) / n

Ft⁺¹ = Forecast for next period

Dt = actual demand in the current period

Dt⁻¹ = Demand in the previous period

n= Number of periods on average

4. Casual Forecasting

This method involves forecasting product demand by analyzing demand alongside other external factors such as price changes, market campaigns, and economic conditions. There are various causal forecasting methods, such as simple linear regression and multiple linear regression.

Let's discuss simple linear regression. It estimates how a particular factor, such as price, can affect product demand.

Formula Y = a + b X + ε

Y = Forecast demand

X= independent variable

ε = random error term

a = intercept

b = slope

5. Rule-Based/Heuristic Methods

This method uses formulas, expert opinions, or predefined rules to estimate market demand for products. There are various heuristic methods, such as the reorder point method and the economic order quantity. Let's discuss economic order quantity.

Formula EOQ = √(2DS / H)

D = annual demand

S = ordering cost per order

H = Holding cost per product per year

Core Forecasting Formulas And Practical Worked Examples

1. Lead Time Demand

Lead time demand = (Average daily demand × Lead time)

Average daily demand = 60 units/day

Lead time = 10 days

Lead time demand = 60×10 = 600 units.

2. Safety Stock Formula

It is the extra inventory that businesses should keep in mind to meet unexpected demand.

Safety stock = (Maximum Daily Usage × Maximum Lead Time) − (Average Daily Usage × Average Lead Time)

- Maximum Daily Usage = The highest number of units sold or used in a day

- Maximum Lead Time = The longest supplier lead time (in days)

- Average Daily Usage = The typical number of units sold or used per day

- Average Lead Time = The usual time (in days) it takes to receive new stock

For Example:

- Maximum daily usage = 100 units

- Maximum lead time = 10 days

- Average daily usage = 80 units

- Average lead time = 7 days

Safety Stock = (100 × 10) − (80 × 7)

Safety Stock = 1000 − 560 = 440 units, So, Business should keep 440 units as safety stock to protect against delays or sudden demand spikes.

3. Reorder Point

The reorder point tells when to reorder a quantity to avoid out-of-stock issues in the warehouse.

Reorder Point (ROP) = Lead Time Demand + Safety Stock

For example, if the lead time demand is 500 units and the safety stock is 75 units, then

Reorder point = 500 + 75 = 575 units

The business can place the next order when the inventory falls reaches 575 units.

4. Forecast Accuracy Metrics

Data Table:

| Week | Actual (A) | Forecast (F) |

|---|---|---|

| 1 | 100 | 90 |

| 2 | 120 | 110 |

| 3 | 130 | 120 |

| 4 | 150 | 145 |

1. Mean Absolute Percentage Error (MAPE)

Formula: MAPE = (1/n) × Σ(|A − F| / A) × 100

Step-by-step calculation:

- MAPE = [(10/100) + (10/120) + (10/130) + (5/150)] / 4 × 100

- MAPE = (0.10 + 0.083 + 0.077 + 0.033) / 4 × 100

- MAPE = (0.293 / 4) × 100

- MAPE = 0.0733 × 100

- MAPE = 7.33%

Final Answer: The Mean Absolute Percentage Error (MAPE) = 7.33% - That means Business forecast is 92.67% accurate.

2. Mean Absolute Deviation (MAD)

Formula: MAD = Σ|A − F| / n

Step-by-step calculation:

- MAD = (|100−90| + |120−110| + |130−120| + |150−145|) / 4

- MAD = (10 + 10 + 10 + 5) / 4

- MAD = 35 / 4

- MAD = 8.75

Final Answer: The Mean Absolute Deviation (MAD) = 8.75 units - So, on average, the forecast deviates by 8.75 units from the actual demand.

Step-by-Step Implementation Roadmap

1. Baseline Audit

A business owner needs to collect data for 6 months and verify the inventory turns, stockout rate, and forecast accuracy. The business also needs to identify the problems it consistently faces, such as overstocking or understocking.

2. Pilot Test

A business owner needs to run two to three forecasting methods, such as the manual or moving-average method, to assess stock-out rates and inventory levels.

3. Integration With Systems

A business owner needs to link the forecasting tool to the enterprise resource planning and warehouse management system. The owner needs to add an alert system for low stock levels or forecast errors.

4. Continuous Improvement

The business owner needs to monitor the stockout rate and forecast accuracy continuously.

Different Types of Tools For Inventory Forecast

1. NetSuite

NetSuite is a cloud-based ERP software that uses past sales data to predict future product demand. The software calculates the reorder point automatically and tracks inventory across multiple locations.

2. Bright Pearl

Bright Pearl is the next advanced software that can track inventories in real time on both offline and online sales channels and avoid stockout issues. The software even improves the forecast accuracy of the business.

3. Inventory Planner

It is the next tool that can automatically create purchase orders based on the forecast data. The tool even consolidates all sales and inventory data into a single dashboard.

4. Zoho Inventory

Zoho Inventory is a cloud-based forecasting tool that can easily manage multiple warehouses. The tools track inventory and sales across various platforms and showcase them in a single dashboard. Zoho even provides reports on sales trends and inventory turnover rate.

Common Mistakes And How To Avoid Them

- Using Poor or Incomplete Data: If a business forecasts product demand using improper or outdated sales data, it can lead to stockout issues.

- Depending On A Single Forecasting Model: Using a single forecasting model every time can lead to inefficiencies.

- Overdependence on Manual Forecasting: When a business uses manual forecasting methods and performs manual calculations, it increases errors.

- Ignoring Seasonality: If a business forecasts product demand without accounting for peak season, it can lead to overstocking and stock-out issues.

Final Words

Inventory forecasting plays a vital role in business profitability. A business can utilize advanced software and track key performance metrics, such as forecast accuracy and inventory turnover rate, for long-term success in a competitive market.