A research study states that more than 79 percent of the businesses reported higher revenue growth after utilising end-to-end supply chain management.

Today, customers expect fast deliveries of their ordered products along with efficient return handling and quick refunds. A business depending on traditional supply chain methods can no longer meet such demands. It should adopt new and advanced technologies like automation and a warehouse management system to reduce errors and increase visibility in the entire supply chain.

What is an End-To-End Supply Chain?

End-to-end supply chain is a complete process of the entire journey of the product, i.e, from sourcing raw materials to manufacturing, storage, shipment, delivery, and customer support after sales. Here, the information flows smoothly between suppliers, manufacturers, warehouse storage providers, and logistic partners.

End-to-end supply chain optimises the production process and ensures that customers will receive good quality products on time.

End-to-End Supply Chain VS Traditional Supply Chain

Traditional Supply Chain

The traditional supply chain focuses only on selected areas. There is no coordination between the suppliers, manufacturers, or logistics partners. Let's discuss with an example. A supplier provides raw material to the manufacturer. The manufacturer will produce the product and transport it to the distributor. The distributor will further transport the product to the retailer, and then to the customer. Each stage manages its own processes independently and is unaware of the entire supply chain process. This process is less flexible and can be prone to errors. If market demand changes suddenly, suppliers and manufacturers will have no way of knowing about it. It can lead to overstocking and out-of-stock issues.

The traditional supply chain primarily relies on forecast data, which can result in delays in product delivery to customers.

End-to-End Supply Chain

End-to-end supply chain connects each stage of the product journey, i.e, from sourcing raw materials to delivery. There is proper coordination between the suppliers, manufacturers, and delivery partners. 3PL Companies use advanced systems like AI, data analytics, and ERP systems, and adjust workflows based on customer demand in the market.

Let's discuss with an example. Amazon works with various manufacturers. They get raw material from suppliers and produce the product. The products are made in a manufacturing Company according to the demand forecasts. The products are further transferred to the Amazon fulfillment centers. When a customer places an order, the advanced software automatically selects the nearest warehouse with stock availability. The Amazon delivery network ships the product further to the customer.

Components Of End To End Supply Chain

The components of the end-to-end supply chain are as follows.

1. Procurement

It is the stage where a business buys raw materials from the suppliers—a business needs to select suppliers who provide good raw materials at an affordable cost.

2. Manufacturing And Production

The manufacturing Company turns the raw materials into finished products.

3. Warehousing And Inventory Management

The staff of the warehouse checks the products that arrive from the manufacturing company and stores them in the warehouse. The warehouse leverages advanced technology to avoid stockout or overstocking issues.

4. Order Management And Fulfillment

Whenever a customer orders any product from the Amazon website or app, the order details are sent automatically to the nearest warehouse. The staff picks up the product and does the packaging so that it will maintain its quality during transit.

5. Distribution And Logistics

Goods are further transported from the warehouses to the customer's doorstep by air, sea, rail, or truck.

6. Reverse Logistics And Returns

Sometimes the customer does not like the ordered product and places a return request. The staff of the company picks up that product and brings it back to the warehouse. The staff carefully inspects the product and decides whether to refurbish, recycle, or restore it to the shelf.

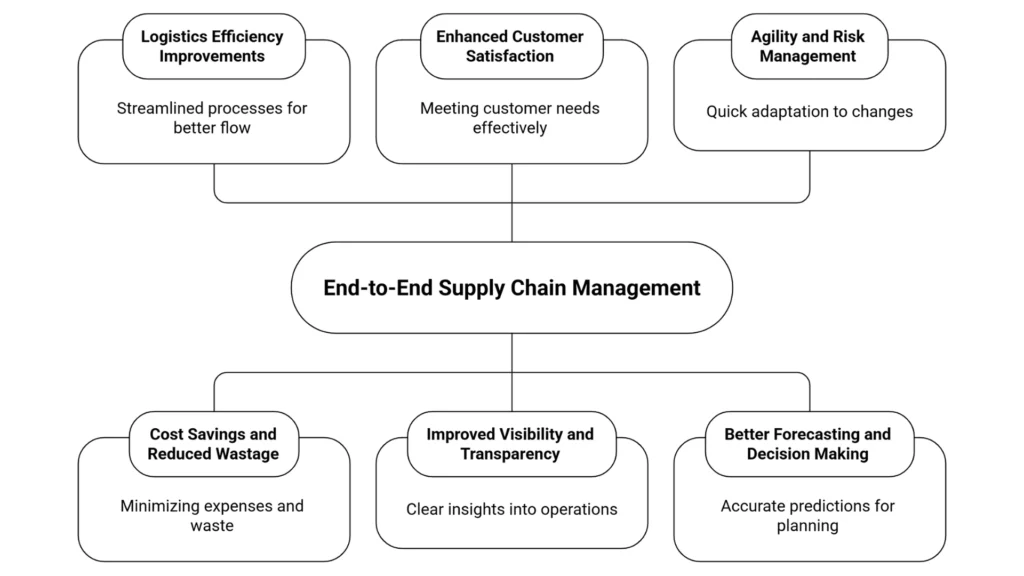

Benefits of End To End Supply Chain Management

The benefits of end-to-end supply chain management are as follows.

1. Logistics Efficiency Improvements

End-to-end supply chain management connects all the processes. So there are fewer chances of delay in delivering products to the customer.

2. Cost Savings And Reduced Wastage

End-to-end supply chain management leverages technology to optimize inventory management in the warehouse, thereby mitigating issues such as overstocking and understocking.

3. Enhanced Customer Satisfaction

Customers get their ordered products faster through the end-to-end supply chain, and this increases customer satisfaction.

4. Improves Visibility And Transparency

End-to-end supply chain management increases visibility at every stage of the process, i.e, from procurement to delivery, which helps to detect problems earlier.

5. Agility And Risk Management

Businesses can respond quickly to sudden changes in market demand through end-to-end supply chain management and mitigate risks accordingly.

6. Better Forecasting And Decision Making

Companies can better forecast product demand and make better decisions through end-to-end supply chain management.

Key Technologies Powering End-To-End Supply Chain

- Supply Chain Automation Tools: Automation tools can reduce manual work, especially in order processing and inventory management.

- AI And Machine Learning In Forecasting: AI and machine learning analyze a vast amount of data and optimize stock levels in the warehouse. This avoids the problem of overstocking and understocking issues.

- IoT For Real-Time Tracking: The IoT uses sensors for tracking inventories while storing them in the warehouses or during transit.

- Blockchain For Transparency: Blockchain records transactions across the entire supply chain, preventing fraud.

- Cloud-Based ERP And WMS: An enterprise resource planning and warehouse management system in the cloud enables businesses to manage logistics and inventory from anywhere.

Common Challenges in Implementing End-To-End Supply Chain

End-to-end supply chains face a few challenges. Here are some of them.

1. Legacy Systems And Data Silos

Today, most businesses use outdated systems that will not communicate between suppliers, manufacturers, warehouse providers, or logistics providers. The data gets stuck only in one department, and this leads to inefficiencies in the supply chain.

2. High Implementation Costs

Implementing AI, machine learning, or leveraging advanced cloud-based software requires a high initial investment, which is not possible for all small and medium-scale enterprises.

3. Supplier Dependency Risks

If a business depends on a single supplier and it does not deliver products on time, then it can adversely affect the entire supply chain. For example, there can be delays in product delivery, which can dissatisfy customers.

4. Global Disruptions

Global disruptions like pandemics, wars, or natural disasters can cause delays in transporting products, and this can cause inefficiencies in the supply chain.

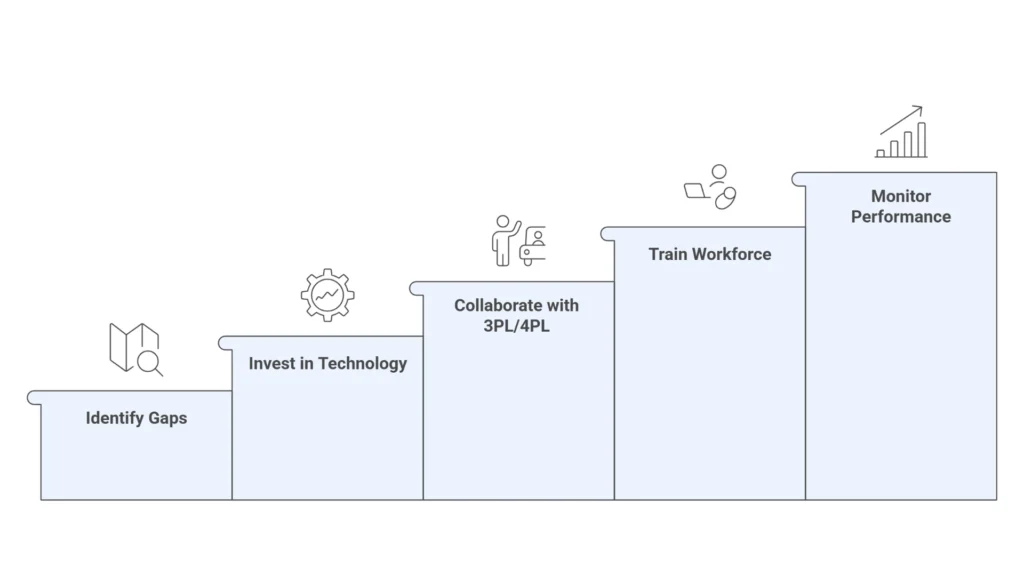

How To Build An Effective End To End Supply Chain?

A business can build an effective supply chain by utilising the following things.

1. Access Current Supply Chain Gaps

A business should assess the weaknesses in the entire supply chain. There can be delays in delivering products, unreliable suppliers, or a lack of visibility. The business should then try to implement technology or choose reliable suppliers to improve supply chain efficiency.

2. Invest In the Right Technology Stack

The business should utilize tools like ERP systems, IoT, and automation to reduce errors and enhance supply chain efficiency.

3. Collaborate With Reliable 3PL/4PL Partners

The business can collaborate with a reliable and reputable third-party logistics company or fourth-party logistics provider if it does not want to invest a high amount in warehousing and logistics, or advanced software and technology.

4. Train Workforce

The business should train its staff regarding the use of advanced technology. It ensures that all the supply chain activities will be done smoothly.

5. Monitor Performance With KPIs

The business should use KPIs like delivery time and cost per shipment to track supply chain efficiency and improve consistently.

Final Words

Today, customers like to order from an ecommerce company in India that can deliver products faster and efficiently and streamline return logistics. Hence, businesses need to integrate procurement, manufacturing, warehousing, logistics, and returns in a single connected system to meet customer demands and increase brand reputation in the market.