Distribution and Fulfillment centers are storage facilities that keep goods and products, do inventory management and order fulfillment on behalf of the businesses.

The Indian logistics and ecommerce sector is experiencing rapid growth every year. Research says that the logistics market in India will reach USD 380 billion by 2025. It demands faster order processing. Hence, most business owners turn to Distribution and Fulfillment centres for efficient storage and fast delivery solutions.

What Is a Fulfillment Center?

A fulfillment center is a 3PL warehouse that picks, packages, and ships products on behalf of the business.

Fulfillment centers play an integral part in the supply chain process. Nowadays, most fulfillment centers leverage advanced technology like a warehouse management system for tracking real-time inventories in the warehouse. It reduces problems of overstocking and understocking the products of a business.

What is a Distribution Center?

A distribution center is a warehouse that moves goods to other warehouses, fulfillment centers or retailers and wholesalers. They are vital in the supply chain, just like fulfillment centers.

Products arrive in the distribution center in bulk from suppliers or manufacturers. The distribution center staff inspects them properly and then stores them in their designated places. Distribution centers use various storage systems like pallet racking, shelves, etc.

Distribution Center vs Fulfillment Center

1. Purpose

Fulfillment involves picking and packaging the ordered product and shipping it to the customer's doorstep. But a distribution center handles bulk inventory and distributes it to the retail outlets or fulfillment centers rather than delivering it to the customer.

Let's discuss with an example. A company sells cosmetic products online and stores them in a fulfillment center. Whenever a customer needs a cosmetic product, the staff picks it up, does proper packaging, and hands it to the shipper to deliver it to the customer.

Now let's talk about distribution centers. It receives cosmetic products in bulk from the manufacturer and stores them. Whenever it receives an order, the staff do the packaging and distribute it to various retail stores.

2. Size

The size of the fulfillment center depends on the needs of a particular e-commerce Company. But distribution centers are usually large warehouses as they store inventories in bulk quantities.

3. Capabilities

Fulfillment centers usually have storage bins, labeling machines and packing stations. But distribution centers have pallet jacks and platform trucks.

How To Choose The Right Choice For Your Business?

1. Know The Customer Base

If your customers are individual online shoppers, you must choose fulfillment centers for storing products. You must select a distribution center if your customers are retailers or wholesalers.

2. Evaluate Order Volume

You must choose a fulfillment center if you have small individual orders to ship. But if you need to ship orders in bulk quantities, then you need to select a distribution center.

Key Functions of Both Distribution And Fulfillment Center

Functions Of A Distribution Center

1. Receives Inventory And Storage

The distribution center receives inventories in bulk quantities. The staff inspects it and stores it on shelves, pallets or racking systems.

2. Inventory Management

Distribution centers use advanced technology like barcodes and RFID tags for maintaining stock levels in real time.

3. Packaging

Whenever the distribution center receives an order, the staff does the packaging of the ordered products.

4. Shipping

The staff then shifts the packaging products to the shipping areas and loads the products on trucks, aeroplanes or ships. The products are further shipped to the retailers or wholesalers.

Functions Of A Fulfillment Center

1. Inventory Storage

The fulfillment center receives products from the manufacturer. The staff inspects the product thoroughly and stores it on the shelves.

2. Receive Order

When a customer orders a product from the e-commerce site, the order details are sent automatically to the fulfillment center.

3. Picking And Packaging

The fulfillment center staff picks up the ordered product from the shelf and does a thorough packaging so that it will not get damaged during transit.

4. Shipping

The staff hands the packaged product to the shipper, who delivers it to the customer's doorstep.

5. Return Handling

The customer sometimes does not like the ordered product and places a return request. The fulfillment center staff picks up the item from the customer and brings it back to the fulfillment center.

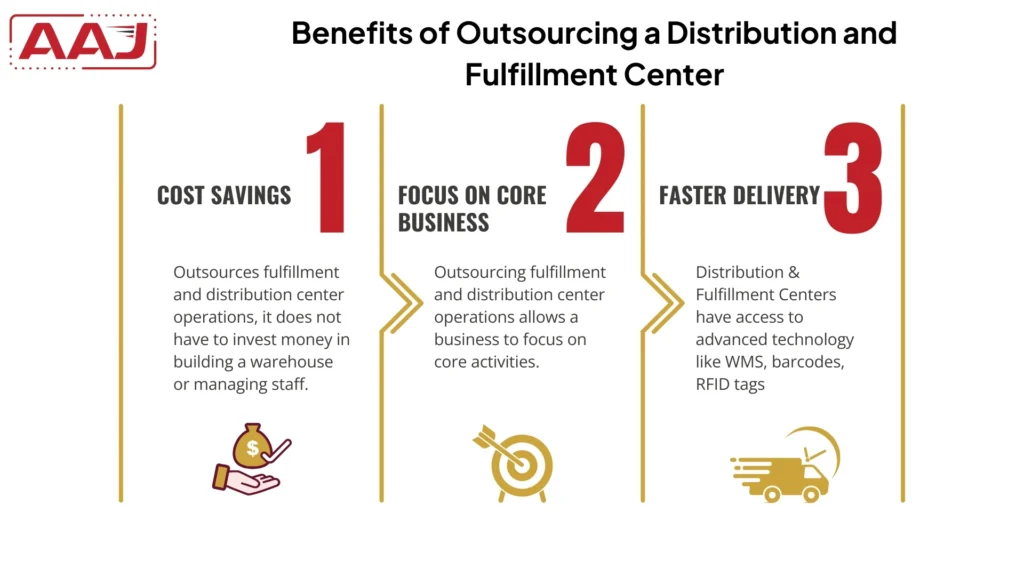

Benefits of Outsourcing a Distribution and Fulfillment Center

There are various benefits of outsourcing a Distribution and Fulfillment Center. Here is a list of them below.

1. Cost Savings

When a business outsources fulfillment and distribution center operations, it does not have to invest money in building a warehouse or managing staff. It does not have to buy equipment like forklifts. So, outsourcing Distribution and Fulfillment Center operations significantly saves money for the business.

2. Focus On Core Business

Outsourcing fulfillment and distribution center operations allows a business to focus on core activities like product development, exploring new markets and many more.

3. Faster Delivery

Most Distribution and Fulfillment Centers have access to advanced technology like warehouse management systems, barcodes, RFID tags and many more. It enables fast delivery to customers or retailers.

Final Words

Choosing between the Distribution and Fulfillment Center depends on your business's product type. If you want to ship products directly to customers and handle returns, you need to choose a fulfillment center for storing and shipping products. Simultaneously, you must select a distribution center if you handle bulk products and ship them to retailers. Choosing the right one can efficiently manage your supply chain process and enhance your brand reputation.