The Indian B2B logistics market was $200 billion in the year 2020. It has now increased to $325 billion. This shows the growth of B2B industries in our country. Supply chain management plays an important role in the growth of the B2B sectors.

B2B supply chain management means managing the flow of goods and materials between businesses. An effective B2B supply chain can reduce costs and avoid problems of overstocking and out-of-stock issues. It even improves brand reputation in the market.

What Is B2B Supply Chain Management?

B2B supply chain management refers to the flow of materials and services effectively between businesses. It involves everything from procuring raw materials to manufacturing, inventory management, warehousing, logistics, and final delivery to the business. A well-coordinated network can reduce logistics costs and lead times. It improves brand reputation and the market.

B2B Supply Chain Example

Let's discuss with an example. A manufacturer procures raw materials from various suppliers and then assembles the products. The materials are further transported to the distributors or wholesalers, who further sell them to the retailers. Each node in the B2B supply chain management requires effective coordination, management, and transparency.

Difference Between B2B and B2C Supply Chain

| Key Features | B2B Supply Chain | B2C Supply Chain |

| Product delivery | Here, one business delivers products to another business, which can be wholesalers or retailers. | Here, the business delivers products directly to the customers. |

| Contract | It involves a long-term contract between the businesses. | A customer makes one-time or infrequent purchases from the business. |

| Order Volume | It involves a large bulk product order. | It involves small quantities of order. |

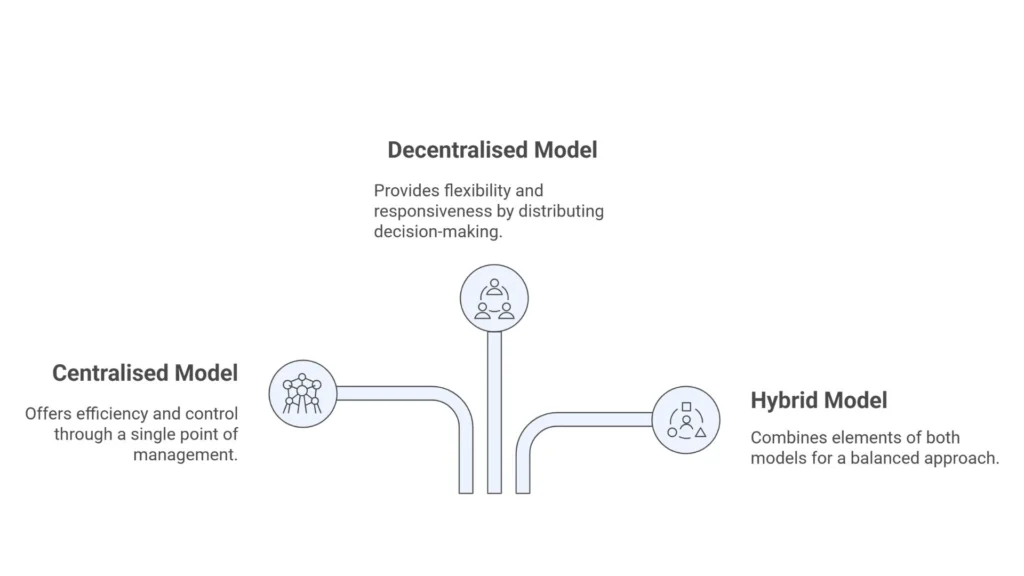

Different Types Of B2B Supply Chain Models

There are various types of B2B supply chain models. Here is a list of them below.

1. Centralised B2B Supply Chain Model

Here, a single central location or the headquarters of a business controls and manages all the important supply chain operations like procurement, manufacturing, and logistics. There are various benefits of this model, such as streamlined coordination between all the teams involved in the supply chain. There is consistency in the quality of the products. But there are a few disadvantages, like if there are any issues in the central location, i.e, in headquarters, then it can adversely affect the entire supply chain.

2. Decentralised B2B Supply Chain Model

Here, the business unit or regional office takes independent decisions regarding procurement, production, logistics, and distribution. A decentralised model is great for larger companies that operate in various regions or countries. It allows faster decision-making and enhances customer satisfaction. Supply Chain Disruption in one area will not adversely affect other areas. But a decentralised model has limited visibility. It can lead to higher operational and warehousing costs.

3. Hybrid B2B Supply Chain Model

A hybrid model combines both centralised and decentralised B2B supply chain management models. It means the central hub manages aspects like procurement and supplier section, while the local branches handle customer service and goods delivery. There is improved visibility and communication across the entire supply chain network. The regional branches can even instantly cater to the market demands. But it has a few disadvantages, like improper coordination between the central branch and local branch, which can lead to supply chain operation inefficiencies.

Key Benefits Of Effective B2B Supply Chain Management

An effective B2B supply chain management has several benefits. Here is a list of them below.

- It builds a stronger relationship with the suppliers.

- An effective B2B supply chain management can help a business manage inventory in a better way and avoid problems like overstocking and understocking issues.

- A reliable and effective supply chain management ensures faster deliveries to business customers and improves brand reputation in the market.

- It reduces wastage and thus lessens the cost of the business.

Key Strategies For Growth In B2B Supply Chain Management

1. Digital Transformation

A business buyer can use advanced technology like ERP, cloud-based systems, or AI to manage inventories or forecast product demand in the market. This can lead to real-time inventory tracking or faster order processing.

2. Resilient Sourcing

A B2B supply chain should diversify suppliers to avoid disruptions. It can even keep extra stock in its B2B warehouse to meet sudden demand in the market.

3. Sustainability

A business can use electric vehicles to reduce carbon emissions and fuel costs. Again, it can use advanced technology to choose the efficient route for transporting goods.

4. Collaboration

A business seller should have strong collaboration with suppliers and distributors. This ensures smoother operations in the entire supply chain.

Common Challenges In B2B Supply Chain

A B2B supply chain even faces a few challenges. They are in the list below.

1. Demand Supply Mismatches

If a business overestimates the product demand, then it can lead to high storage costs. Again, if the business underestimates the product demand, then it can lead to lost sale opportunities and have a negative impact on customers.

2. Supply Chain Disruptions

If the business buyer depends on a single supplier and it does not deliver products on time, then it can adversely affect the entire supply chain.

3. Rising Transportation Costs

Fuel prices may rise over time. Again, choosing an inefficient route can even increase the transportation costs of the business.

4. Lack Of Visibility Across The Entire Supply Chain

Businesses cannot track their inventory or shipments without proper visibility.

5. Compliance And Regulatory Issues

A B2B supply chain management operates across various regions. They have different rules and regulations. But if it fails to comply with laws or standards, then it leads to penalties.

Final Words

A business can have effective B2B supply chain management by adopting advanced technology like AI, robotics, and warehouse automation. It should even coordinate with multiple suppliers and should have good relationships with them. This will reduce lead times and improve customer satisfaction.