Today, warehouse sorting has become an essential pillar of a successful e-commerce and retail business. It involves sorting products by type, weight, size, or shipping destination. Earlier warehouses used manual processes for sorting products. Workers used to visually check labels and sort products by size or weight. But now, most warehouses use advanced technologies such as conveyor belts and robotics to improve sorting. It even enhances the business's overall supply chain efficiency.

What Is Warehouse Sorting?

Warehouse sorting is the process of organizing and separating products by weight, size, and market demand. It is essential for both inbound and outbound goods.

It is the step where items are organized based on factors such as order type, size, destination, priority, SKU, or customer requirements. That makes picking, packing, and dispatching faster and more accurate.

Where Sorting Fits In Supply Chain Workflow?

Warehouse sorting plays a vital role in various stages of the supply chain process.

1. Inbound logistics

When a warehouse receives inventory from sellers or manufacturers, the staff need to sort it by size or demand and place it in the correct location.

2. Storage & Inventory Management

The staff moves the items from the receiving zones to the storage locations. The staff sorts the products and places them on shelves or racks based on demand or size.

3. Outbound Logistics

The staff need to sort outbound goods by delivery route and shipping carrier.

4. Reverse Logistics

The warehouse staff sorts returned products based on condition, determining whether they will be restocked, refurbished, or recycled.

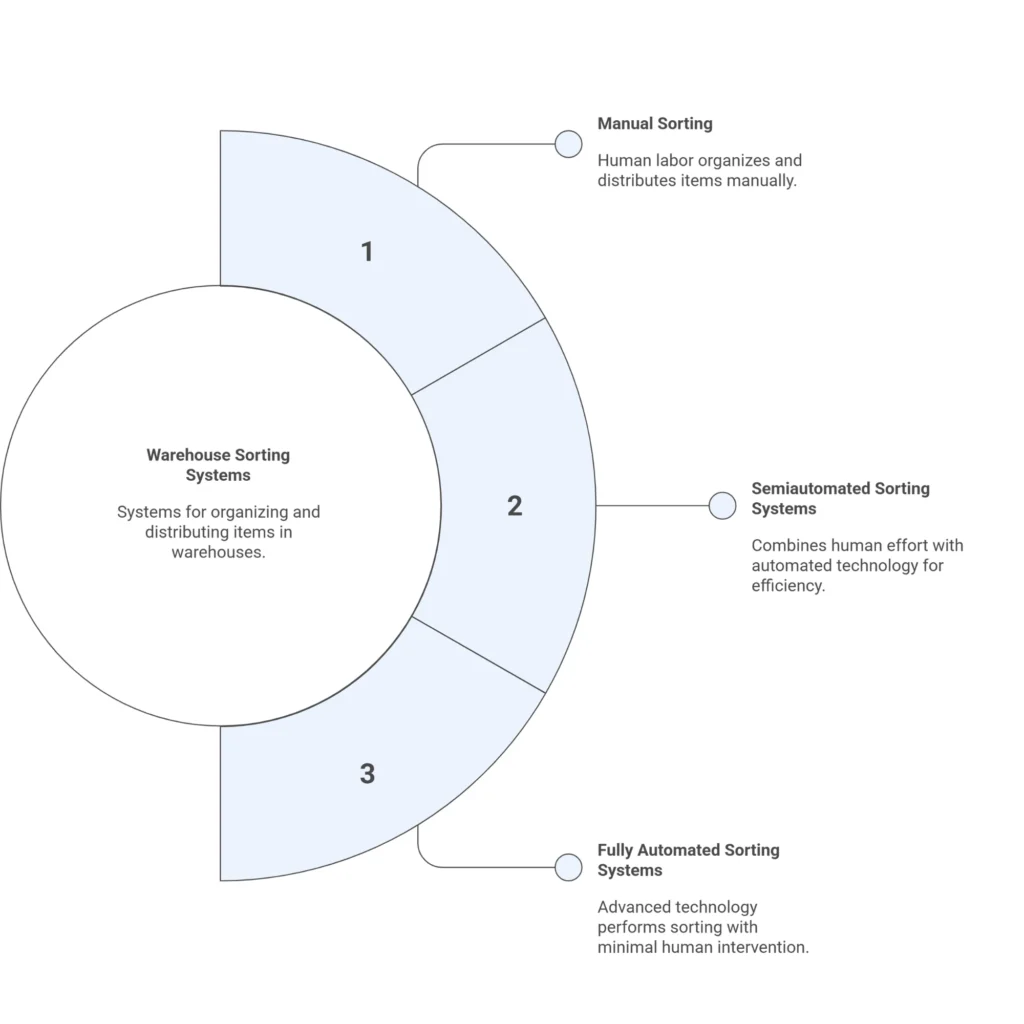

Types Of Warehouse Sorting Systems

There are usually three types of warehouse sorting systems. They are in the list below.

1. Manual Sorting

Manual sorting relies heavily on human force. The warehouse staff sorts the product by size, weight, or demand type. This method is suitable for startups or small enterprises, as it requires low investment. But it has a few limitations, such as the manual sorting process being quite time-consuming and prone to errors. The business can face challenges during peak seasons.

2. Semiautomated Sorting Systems

Semiautomated systems use human effort along with mechanical or digital technology to improve the order fulfillment process efficiency. For example, the business can use barcode scanners or conveyor belts to improve efficiency. Semiautomated warehouse sorting method reduces physical strain on workers and is faster and more accurate compared to manual sorting. But it has a few limitations, like the business needs to invest more in utilizing semi-automated sorting systems.

3. Fully Automated Sorting Systems

Fully automated sorting systems use robotics, AI, and sensors to sort inventory. These systems reduce the business's labor costs. Simultaneously, the method is highly accurate compared to the other two sorting systems. Fully automated sorting systems are ideal during peak seasons. But it has limitations, like the business needs to invest more in utilizing a fully automated warehouse sorting system. Again, the company needs technical support to utilize this string system.

How Warehouse Sorting Systems Improve Accuracy?

1. Reduction Of Human Errors

Manual sorting usually leads to errors. But when a business utilizes semi-automated or completely automated warehouse sorting systems, it reduces errors. For example, a company can use barcode or RFID scanning for verifying products.

2. Better SKU Management

Warehouse sorting systems organize products based on their size, weight, demand frequency, and destination. It improves product visibility in the warehouse facility.

3. Data Driven Decision Making

Today, businesses use advanced technology for sorting products. This not only improves the warehouse layout but also improves supply chain efficiency.

How Do Sorting Systems Increase Throughput And Speed?

- Faster Order Processing: An automated or semiautomated sorting system enables faster order processing and enhances customer satisfaction.

- Labor Productivity and Reallocation: Sorting automation reduces employees' physical workload, allowing them to focus on essential tasks in the warehouse.

- Peak Season Efficiency: Order volumes usually rise during peak season—automated or semiautomated sorting systems sort products quickly with no errors.

Impact On Overall Supply Efficiency

- Improves Inbound & Outbound Coordination: Warehouse sorting systems enable a seamless flow between inbound goods and outbound dispatch.

- Route Optimization For Last Mile Delivery: Sorting enables items to be grouped by delivery route and destination zone.

- Better Utilization Of Space & Equipment: Warehouse sorting systems improve the utilization of space within the warehouse.

- Real-time visibility & Predictability: Automated sorting systems, integrated with advanced technologies such as WMSs, improve product visibility.

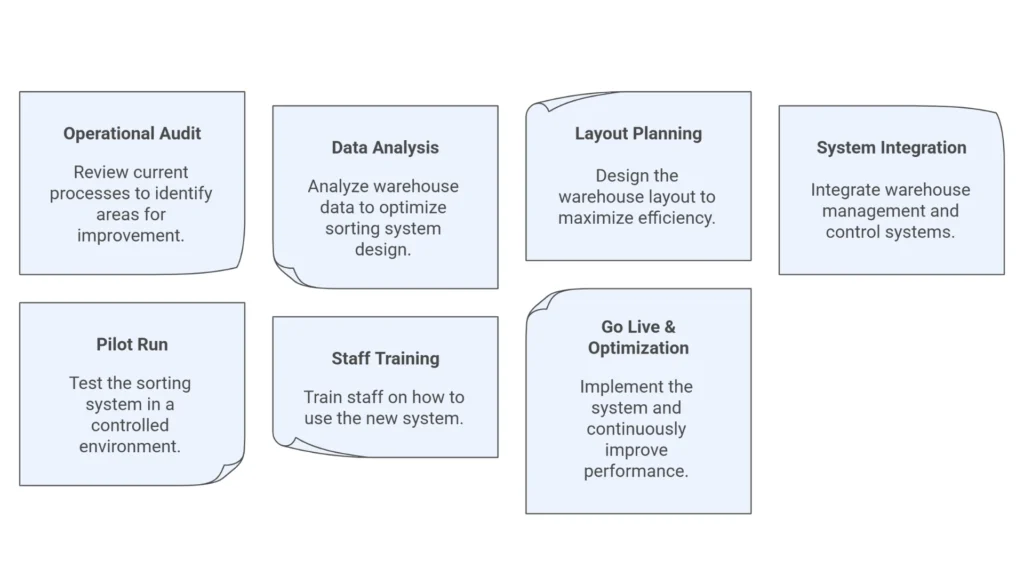

How To Deploy A Warehouse Sorting System?

1. Operational Audit

The business needs first to audit the existing warehouse operations, including current order volumes and the picking, packing, and sorting workflows. The primary purpose is to identify the gaps and utilize the right warehouse sorting system to improve efficiency.

2. Accurate Data Analysis

Accurate data analysis is essential in choosing the right warehouse sorting systems. For example, the business needs to analyze the product dimensions, weight, fragility, and dispatch frequency to select the appropriate sorting system.

3. Layout Planning

Layout planning is one of the first steps in choosing a warehouse sorting system. Its main goal is to design a space that minimizes travel time and allows smooth product flow in a warehouse. The business needs to position the conveyors or packing stations to reduce workers' movement and improve safety in the warehouse.

4. WMS/WCS Integration

The business should integrate the warehouse management system with the warehouse control system to ensure that the sorting system runs smoothly in real time.

5. Pilot Run

Pilot runs involve the testing phase, where the warehouse sorting systems are deployed on a small scale. The pilot verifies whether the barcode scanners, advanced software, and conveyors work together seamlessly.

6. Staff Training

Effective staff training is essential to adopt warehouse sorting systems smoothly. A warehouse with well-trained supervisors and workers will reduce errors and maximize performance.

7. Go Live & Optimization

Here, the warehouse sorting systems operate at full scale. This stage ensures that all the equipment, workforce, and advanced software work seamlessly to enhance order fulfillment accuracy and efficiency. Businesses should optimize the sorting systems from time to time to maintain the speed and reliability.

Common Mistakes To Avoid When Choosing Or Using Sorting Systems

There are a few mistakes that businesses should avoid when choosing or using a sorting system. They are in the list below.

1. Over-automating Too Early

If a business invests heavily in an automated sorting system without adequately analyzing order volumes or workflow requirements, it unnecessarily increases costs. It even creates operational rigidity and delivers low ROI.

2. Ignoring WMS Integration

If a business invests heavily in automated warehouse sorting systems but has poor WMS integration, then it can lead to errors.

3. Choosing Technology That Does Not Scale

If a business chooses a warehouse sorting system that scales well with current volumes but does not handle high demand during peak seasons. This can lead to errors and slow down order fulfillment efficiency in such times.

4. Not training Staff Properly

If a business does not properly train its staff in warehouse sorting, it can slow down supply chain efficiency.

5. Poor Maintenance Schedule

If a business does not properly maintain equipment or other technical systems, it can lead to equipment breakdowns or sensor failures.

Final Words

Today, customers demand a faster order fulfilment process from businesses. Manual warehouse sorting can lead to errors or create inefficiencies in the order fulfillment process. Hence, most of the companies are utilizing semi-automated or automated sorting systems and training their staff to enhance order fulfilment accuracy and efficiency.