Research indicates that 35% of businesses in India experience late shipping due to stockout issues. The main reason behind this is poor inventory planning, where businesses don't restock at the right time. This is where the concept of the reorder point becomes important. Reorder point (also known as reorder level) is the inventory threshold at which the business needs to place a new order to avoid stockout issues. A business needs to optimize the reorder point by keeping the right amount of safety stock and leveraging advanced technology like inventory management.

What Is Reorder Point/Level?

Reorder point is the level of inventory at which a new order should be placed so that incoming stock arrives just in time to meet customers' demand without interruptions. Reorder point plays a vital role in supply chain operation efficiency.

When a business orders more stock, it raises its holding cost. Again, if the product goes out of stock, it dissatisfied customers and can lead to lost sale opportunities. Reorder point indicates the need to replenish the products in the warehouse.

Reorder Point Vs Safety Stock

| Aspect | Reorder Point | Safety Stock |

| Defination | The point at which businesses need to reorder products from the supplier to avoid out-of-stock issues. | Safety stock is the extra stock that a business keeps in the warehouse to meet customer needs, especially during sudden demand in the market. |

| Formula | Reorder point = (Average demand per day lead time)+safety stock | Safety stock = Z ltHere, Z is the service level factor and ltis the standard deviation of demand.The business keeps safety stock based on demand variability. |

What is the Importance Of Reorder Level?

Reorder level or point plays a vital role in business inventory management. Here is a list of them below.

1. Prevents Stockout Issues

It indicates that a business should order products from the supplier before the product goes out of stock.

2. Maintain Smooth Operations

The reorder level allows for a smooth relationship between manufacturers and retailers.

3. Improves Order Fulfilment Process

It allows a business to keep enough stock to meet customer demands. This improves the order fulfillment process and enhances customer satisfaction.

4. Improves Cash Flow

The reorder point in inventory management prevents tying up too much in excess inventory. The capital is available for businesses to meet other needs, like product development or exploring a new market.

Reorder Level Formula - How To Calculate Reorder Point

Reorder point/level = (Average daily demand lead time in days) + (safety stock)

There are three essential components of the reorder level. A list of them is outlined below.

1. Average Daily Demand

Average daily sales refer to the total number of products sold per year by a business in a particular period. For example, a company sells 8,00,000 computer parts in a year. So the average daily sales will be 8,00,000/365 =2191.7. So the Company sells almost 2191 computer parts per day.

2. Lead time

It is the time a seller takes to deliver the order to the customer. A long lead time results in delays in order processing and satisfying customers. However, a shorter lead time allows a business to pick, pack, and ship earlier to enhance customer satisfaction.

3. Safety Stock

Safety stock is the extra stock a business maintains to meet unexpected product demand in the market. It differs from one business to another.

Let's discuss with an example. A retailer sells 50 chargers every day. So, here, the average daily demand is 50 days.

The supplier takes almost 8 days to deliver the phone charger. So the lead time is 8 days.

The retailer has a safety stock of 90 chargers to meet unexpected demand.

So the reorder point = (50 8) +90 = 490

The retailer should place a new order when the stock drops to 490 chargers.

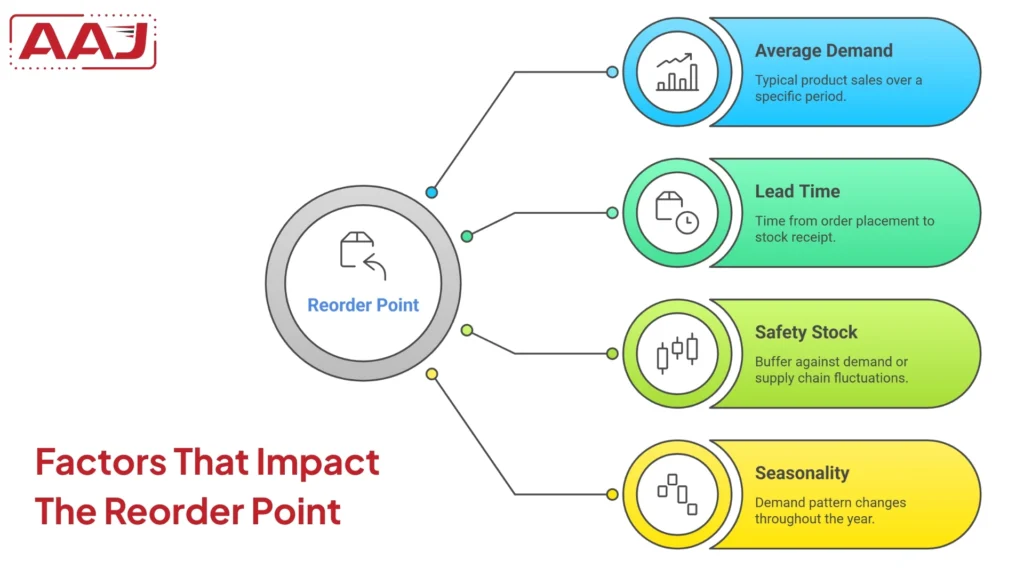

Factors That Impact The Reorder Point

There are a few factors that impact the reorder point. Here is a list of them below.

- Average Demand: When the customer demand increases per day, then there is an increase in the reorder point and the reorder level.

- Lead Time: The reorder point increases when the supplier takes longer to deliver products to the business.

- Safety Stock: If a business collaborates with unreliable suppliers, it should keep more safety stock on hand to meet customer demands. Higher safety stock can lead to a higher reorder point.

- Seasonality: The demand for products can increase in particular seasons or holidays. It can lead to a higher reorder level.

Reorder Point VS. Safety Stock VS. Economic Order Quantity (EOQ)

Reorder Point: It is the point at which businesses need to place a new order to avoid understocking issues.

Safety Stock: It is the extra stock that a business keeps in a warehouse to meet unexpected demand or needs when there are supply chain disruptions.

Economic Order Quantity: The optimal order quantity a business maintains in its warehouse and storage meets customer needs and minimises holding costs.

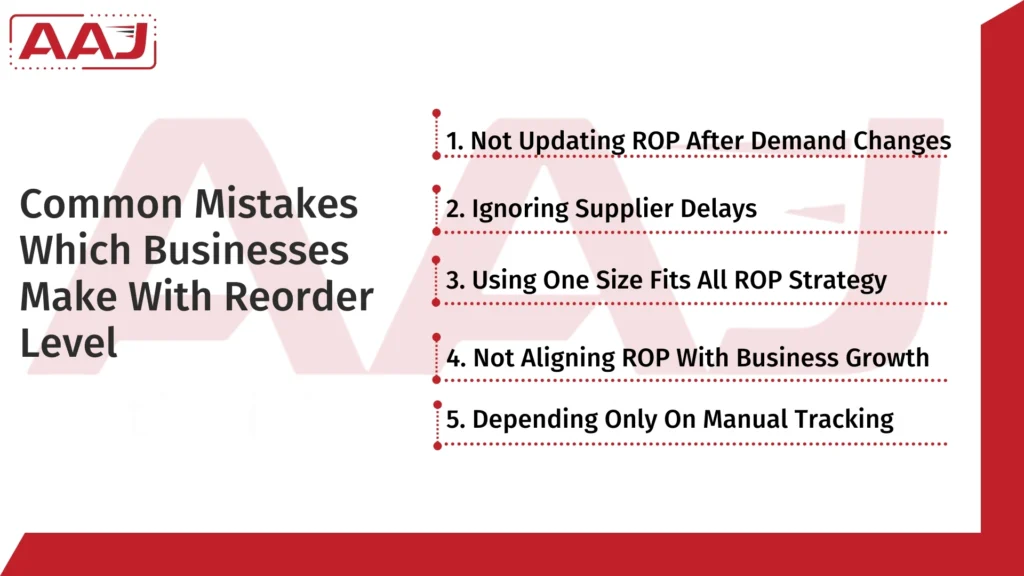

Common Mistakes Which Businesses Make With Reorder Level

1. Not Updating ROP After Demand Changes

Many businesses set the reorder level and forget to update it. This can lead to frequent stockout issues or excess inventory in the warehouse.

2. Ignoring Supplier Delays

Many businesses ignore supplier delays. However, if a supplier delays delivering products, the product can go out of stock before the replenishment arrives.

3. Using One Size Fits All Reorder Point Strategy

Different products stored in a warehouse have different demand patterns and lead times. If a business applies a single reorder level for all the products in the warehouse, then the fast-moving items can soon go out of stock, and slow-moving items can get overstocked in the 3PL warehouse.

4. Not Aligning ROP With Business Growth

When the business grows, the sales and order volume also evolve. If a business stocks with the old ROP point, it can lead to overstocking or out-of-stock issues.

5. Depending Only On Manual Tracking

A business relying only on manual tracking can lead to human errors. A company should leverage advanced and modern warehouse technology to automate various tasks and optimize the reorder level.

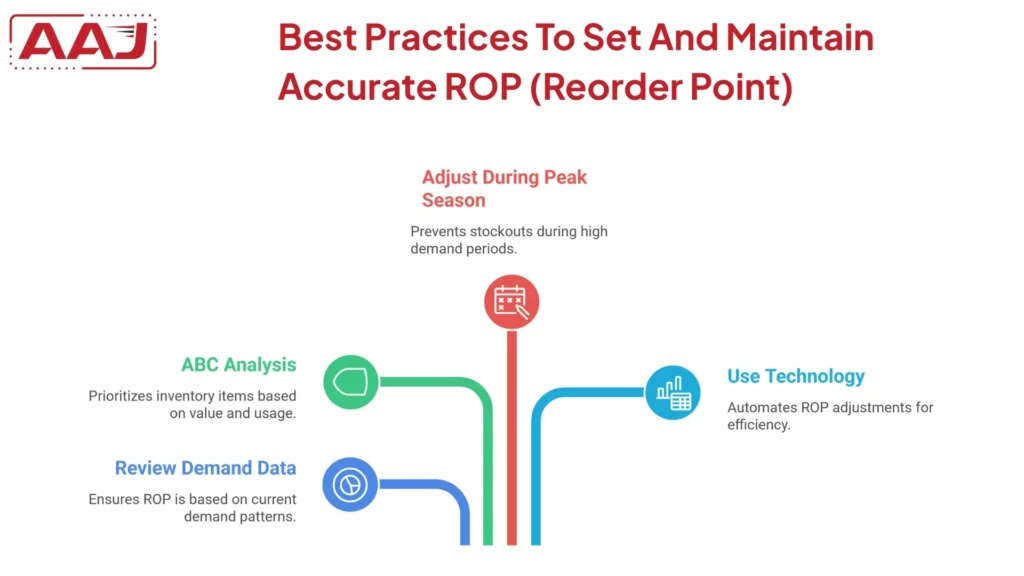

Best Practices To Set And Maintain Accurate ROP (Reorder Point)

1. Regularly Review Demand Data

A business should review demand forecasting data monthly or quarterly to maintain an accurate ROP.

2. ABC Analysis

A business should classify products based on their demand.

- Class A: These items are highly demanding products. It accounts for 80 per cent of the revenue generated by the business.

- Class B: These items have moderate value compared to class A items and account for 15 per cent of the business's total revenue.

- Class C: These items have low value compared to class A and B items. They account for only 5% of the revenue of the business.

3. Adjust ROP During Peak Season

Demand for the product increases, especially during peak season and holidays. The lead time increases because suppliers are usually busy during the peak season. The business should adjust the ROP to avoid stockout problems.

4. Use Technology For Dynamic Reorder Points

Manually tracking inventories can lead to errors. The business should use advanced technology like a WMS, OMS and enterprise resource planning to minimise errors.

Final Words

Inventory management plays a vital role in effective supply chain management of a business. Reorder point is critical for businesses to avoid overstocking or out-of-stock issues. However, companies must know average daily demand, lead time, and safety stock to calculate the reorder point/level.