A warehouse plays an important role in supply chain efficiency. It not only stores goods and products but also packages the ordered product and hands it to the shipper. Proper warehouse management ensures adequate inventory management, timely deliveries, and enhances customer satisfaction.

But most of the warehouse companies struggle to manage their warehouses because of disorganized warehouses and ineffective management practices. Warehouse owners can implement the 5S warehouse system to overcome these challenges. It was initially developed in Japan, and its primary goal is to organize the warehouse space and enhance operational efficiency.

What Is 5S In Warehouse Management?

5S warehouse management is a systematic approach that optimises the space and declutters the unnecessary inventories inside the warehouse. Its main function is to speed up the order fulfillment process and improve brand reputation in the market.

In simple words, a 5S warehouse management system can convert a cluttered and inefficient warehouse into an efficient and well-organised space and enhance productivity.

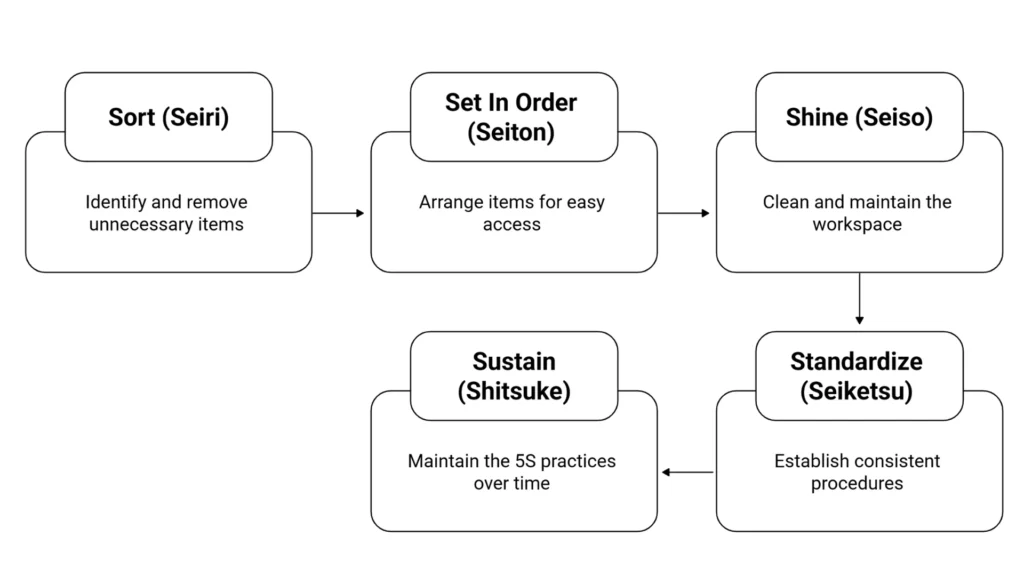

Here, the 5S refers to five Japanese words like seiri (sort),seiton (set in order),seiso (shine),seiketsu (standardise), and shitsuke (sustain).

The 5S warehouse management system originated in 1950 as a part of the Toyota production system. Its main goal was to reduce wastage and improve safety in the work organisation. Today, 5S warehouse management is used in various industries, including the supply chain and logistics industries.

Why 5S Matters In Modern Warehouse Operations?

A warehouse plays an essential role in storing and moving the ordered product seamlessly to the customer. But a disorganised and cluttered warehouse facility can cause delays in product delivery, even if it has adopted advanced technology.

5S warehouse management can transform the functions of the warehouse. It matters in a modern warehouse for the following reasons.

Improves Efficiency

When all the inventories are labelled and kept in their designated places, then the staff of the warehouse can find the ordered products quickly and deliver them to the customer.

Improves Space

A cluttered warehouse may always appear full even if the space is available for storing goods. A 5S warehouse method can optimize the space and make enough space for storing more inventory. It makes better use of shelves and racks in the warehouse.

Enhances Safety

A 5S warehouse can declutter the entire warehouse and keep all the inventories in their place. Thus, it prevents workplace accidents and inventory damage.

How To Implement 5S In A Warehouse?

1. Sort (Seiri)

Sorting is the first step to implement 5S in a warehouse. You need to remove all obsolete inventory, empty boxes, and damaged tools and materials from the warehouse. Sorting can reduce warehouse congestion and optimize the space. It thus allows you to store a larger number of inventory without investing in infrastructure.

2. Set In Order (Seiton)

Here set in order means to arrange all the inventories in their designated place. It will improve warehouse space and reduce the time required for searching for a specific inventory.

You need to assign a specific place for storing a particular type of inventory and label it to improve the speed of the order picking process. You can keep highly demanding products near the work areas so that staff can pick them easily.

3. Shine (Seiso)

Here, shine means you need to keep the warehouse clean and tidy so that it becomes a safe and welcoming environment for the staff.

You need to inspect the racks and shelves on a daily basis and try to keep them clean. Again, the staff need to check the conveyors and forklifts periodically to ensure there is no leakage and damage. You can assign cleaning responsibilities to a particular group of staff to have a clean and safe warehouse.

4. Standardize (Seiketsu)

The term standardize here means keeping consistency in the warehouse processes. You need to develop standard operating procedures for sorting, setting in order and cleaning through visual management tools like charts or graphs. You can train your staff so that everyone will follow the standard procedure. It streamlines the warehouse workflows and improves the efficiency of the warehouse management.

5. Sustain (Shitsuke)

The term sustain means maintaining consistently all the standards and procedures listed above. It is one of the most challenging tasks for warehouse staff. You need to monitor the warehouse operations consistently to ensure all the staff follow the standard operating procedures.

Tools And Technologies to Support 5S In Warehousing

There are various tools and technologies to support 5S in warehousing. Here is a list of them.

- Warehouse management system: The Warehouse management system identifies the unsold inventories and optimises the space.

- Barcode and RFID Technology: It tracks inventory in real time and avoids picking errors.

- Cleaning and Maintenance Tools: These tools ensure the warehouse is always well-maintained.

Common Mistakes To Avoid In 5s Implementation

There are a few mistakes that every warehouse company should avoid during 5S implementation.

1. Less Involvement Of Senior Employees

If the senior management shows little interest in 5S warehouse implementation, then the workers will not take it seriously and follow an inconsistent process.

2. Improper Training Of Employees

If the employees are not appropriately trained in planning and maintaining 5S, then it leads to inconsistent results or poor efficiency.

3. Complex Systems

Usage of a complex system or unnecessary documentation can confuse employees, and that results in poor operational efficiency.

4. Neglect The Final Step of 5S Warehouse Implementation

If the warehouse workers fail to maintain the sorting, keep products in their designated places or clean, then it leads to workflow disruptions or errors.

Benefits of 5S for Warehouse Efficiency

5S warehouse management has various advantages. Here is a list of them below.

1. Fast Material Flow

5S warehouse implementation keeps all the inventories in their places. The workers find it easy to identify the ordered products and package them or hand them over to the shipper.

2. Enhances Customer Satisfaction

5S warehouse implementation can improve the order fulfillment process of a business and thus enhance customer satisfaction.

3. Increases safety

A 5S warehouse has clear floor markings and proper storage of goods and products. It prevents accidents and thus increases safety inside the warehouse storage.

4. Reduce Downtime

5S warehouse reduces the time taken to search for a particular type of inventory.

5. Increases Employee Morale

An organized and clean warehouse can boost employee morale. It allows them to work efficiently without any stress or confusion.

Final Thoughts

5S in warehouse management can improve the order fulfillment process of the business. It allows workers to pick up ordered products quickly and deliver products on time to the customers. It even prevents accidents and encourages them to work without stress. However, 5S warehouse implementation poses a few challenges, such as if the employees are not trained, then it decreases the efficiency of the order fulfillment process.