Reorder Level is the point when your stock gets low and you need to buy more, so you don't run out before the new stock comes. Like a "time to refill" signal for your inventory.

A report says Indian businesses lose nearly Rs 92,000 crore annually because of out-of-stock issues. Simultaneously, overstocking can carry storage holding costs by 18 to 25 per cent per year. The reorder level acts as a safeguard and determines the exact point at which the business needs to place a fresh order from the supplier to avoid supply chain disruptions.

What is the Reorder Level?

Reorder level plays a vital role in inventory management. It indicates the order quantity and when to order new stock to avoid stockout problems in the warehouse.

It represents the minimum quantity of products that should be maintained in a warehouse storage to fulfill customer orders.

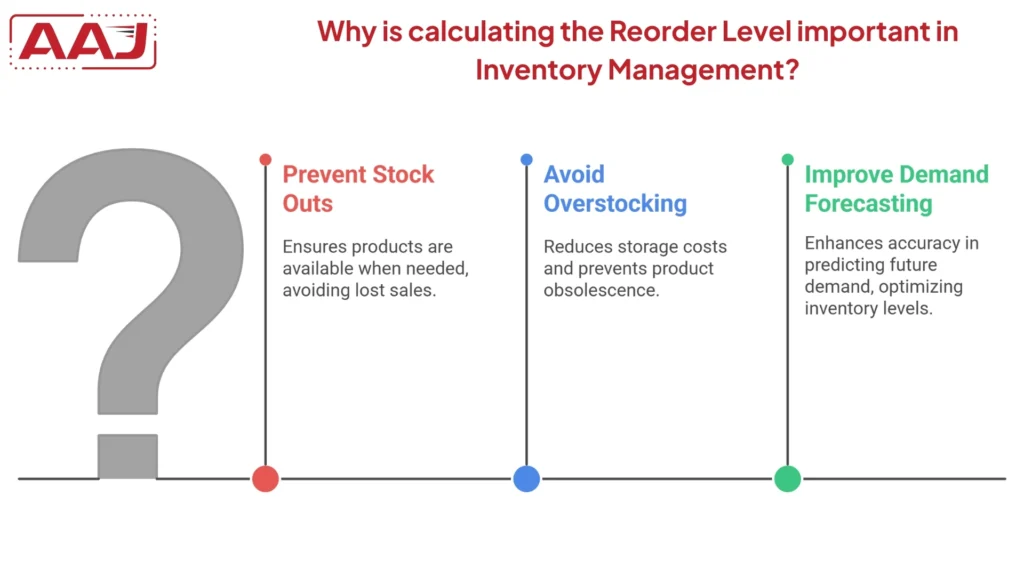

Why is calculating the Reorder Level important in Inventory Management?

The reorder level is crucial while managing warehouse inventories for the following reasons.

1. No Stock Out Problems

Keeping too less inventory in the warehouse can dissatisfy customers and lead to lost sales opportunities. It can help a business maintain an optimum inventory level and avoid stockout issues.

2. Avoid Overstocking Problem

Ordering inventory too early can lead to the storage of excess inventory in the warehouse. It can increase the warehousing costs of the business. The products can become obsolete or spoiled with time. It maintains the optimum inventory and avoids overstocking issues. It even reduces the business's storage costs.

3. Improves Demand Forecasting

When a business calculates reorder levels, it helps it analyse average daily usage, lead time and seasonal trends in the market. It helps a business to achieve accurate demand forecasting.

Formula and How to Calculate Reorder Level With Example

Reorder Level Formula = (Average Daily Usage × Lead time in days) + Safety Stock.

Average Daily Usage: It indicates how many units of the product the business sells daily.

Lead time indicates the number of days it takes for the product to arrive in the warehouse after placing the order.

Safety Stock: Safety stock, also known as buffer stock, is the minimum stock that the warehouse needs to maintain in the warehouse in case of excess demand in the market or delay from suppliers.

For example, a retailer sells mobile phones. He sells almost 10 mobile phones to customers daily. The new mobile phone takes approximately 8 days to arrive from the seller. The safety stock is 20 units.

Reorder level = (10×8) + 20 = 100 units.

So when the mobile phone units drop to 100 units, then the retailer should order the new mobile phones from the seller to avoid stockout problems.

Difference Between Reorder Level and Reorder Quantity

| Feature | Reorder Level | Reorder Quantity |

| Definition | 1. The point at which businesses need to place the new order to avoid stockout problems. | 1. The quantity that a business needs to order every time it reaches the reorder level. |

| Focus | 2.It focuses on when to order products to avoid stockout issues. So it is related to time. | 2.It focuses on how many products to order. So it is related to quantity. |

| Based On Factors | 3.It depends on factors like Average usage of the product, lead time and safety stock. | 3.It depends on factors like economic order quantity, demand patterns, holding cost and ordering cost. |

| Formula | 4.Reorder Level = (Average Daily Usage × Lead time in days) + Safety Stock | 4. Reorder quantity = Underscore 2×D×S Divide by H D = Annual demand of the units per year. S = Ordering cost per order H = Holding cost per unit of the product per year. |

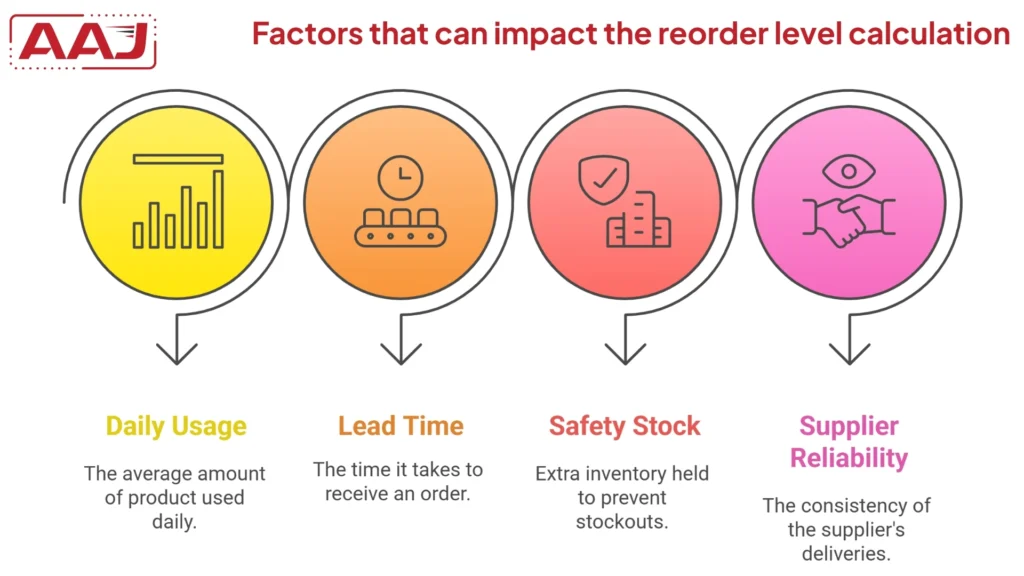

Factors that can impact the reorder level calculation

The reorder level calculation depends on a few factors listed below.

1. Average Daily Usage Rate

It indicates the number of units sold by a business daily. If the daily demand increases, the business will consume its inventory faster. This raises the level to ensure enough stock in the fulfillment center to meet customer demand.

2. Lead Time

Lead time is between placing an order and receiving goods or products. The order level increases with the increase in lead time.

3. Safety Stock

Businesses need to keep a buffer or extra stock to meet customer demand if there is unexpected high demand for products in the market or supplier delays. Higher safety stock increases the reorder level.

4. Supplier Reliability

It determines the consistency with which the supplier delivers the product to the business. If the supplier always makes a delay in delivering products, then the business needs to maintain a higher reorder level to avoid stockout issues.

Final Words

Effective inventory management is highly essential for the success of any business. Stockout problems can lead to unsatisfied customers and decrease brand reputation in the market. The reorder level determines when the company should order products from the seller to avoid stock issues. It depends on various factors like lead time, daily demand of products and safety stock.