A digital warehouse is a modern storage facility that uses modern and advance technology such as software, automation, and smart devices to manage goods, track inventory, and speed up order processing.

Most ecommerce businesses are under constant pressure to meet customer expectations and deliver products efficiently and in the least possible time to the customers. They face challenges while picking, packaging, and shipping products. Managing all these supply chain activities can lead to errors and badly affect the business reputation. There comes the importance of a digital warehouse. It adopts advanced technology and speeds up the order fulfillment processes of your business.

What Is A Digital Warehouse?

A digital warehouse is a technology-powered warehouse storage facility that improves a business's supply chain operations. It adopts technology like warehouse management systems, robotics, and AI, which improves accuracy and reduces human errors. A digital warehouse enables faster delivery of the products ordered to the customer and enhances customer satisfaction.

Difference Between Traditional And Digital Warehouse

| Aspect | Traditional Warehouse | Digital Warehouse |

| Technology | Mnages picking and packaging manually | It uses advanced technology in picking and packaging ordered products |

| Inventory Tracking | It manages and counts inventory manually | It uses advanced software like data analytics and an inventory management system to track the inventories in real time |

| Data Management | It manages data through paper-based or basic systems | It manages data through a centralised digital platform. |

| Efficinecy | Low Chances of errors | High as there is very less chances of errors. |

| Labor | Manual labour is required | Less labour dependency because of embracing automation. |

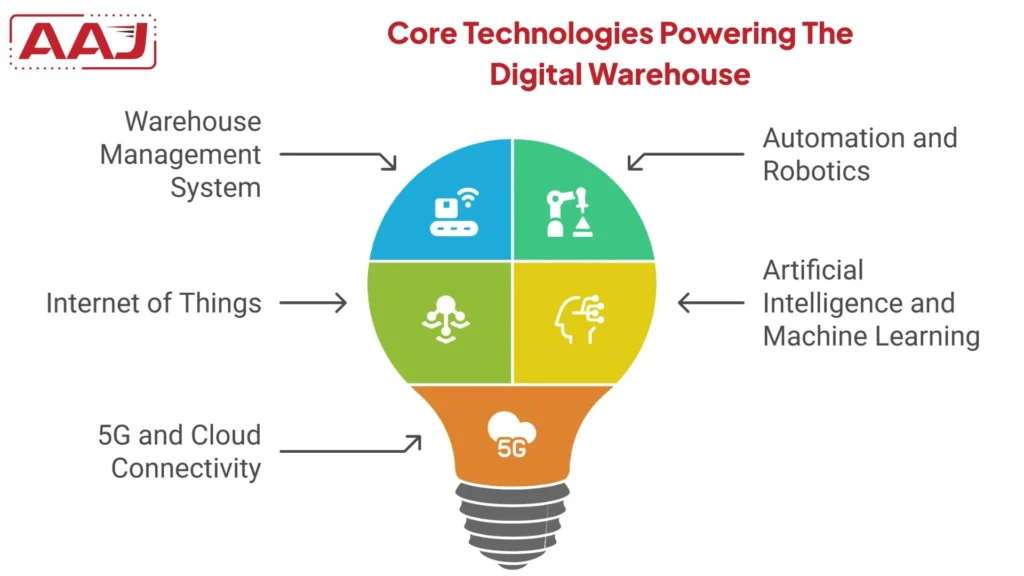

Core Technologies Powering The Digital Warehouse

Digital warehouses depend on various advanced technologies to transform traditional warehouses into highly efficient logistics hubs.

1. Warehouse Management System

The warehouse management system plays a vital role in the digital warehouse. It optimises the warehouse layout, tracks inventories in real time, and integrates with other supply chain solutions systems. The warehouse management system reduces labour costs and efficiently utilises the warehouse space. It avoids the problems of overstocking and understocking in a business.

2. Automation And Robotics

Automation and robotics refer to using advanced software and robotics in the warehouse to reduce costs and improve productivity. For example, automated guided vehicles can transport materials inside the warehouse automatically. Robotic arms can pick up the ordered products from the shelf without human labour.

Robots can even handle hazardous tasks and increase safety inside the warehouse and logistics. Conveyor systems can transport products independently from picking to packing zones.

3. Internet Of Things

Internet of Things uses sensors, RFID tags, and barcode sensors to track inventories in real time and update regarding the stock levels. Consistent data collection can help a business owner to forecast product demand correctly and avoid problems of overstocking and out-of-stock issues. IOT even helps to reduce theft and spoilage of products in the warehouse.

4. Artificial Intelligence And Machine Learning

AI and machine learning revolutionise warehouse operations. Both of them reduce forecasting errors and improve inventory management. The complex operations inside the warehouses can be easily operated with the help of AI and machine learning.

5. 5G And Cloud Connectivity

5G provides ultra-fast data transmission, essential in an automated warehouse. Cloud connectivity allows management to control warehouse operations from anywhere.

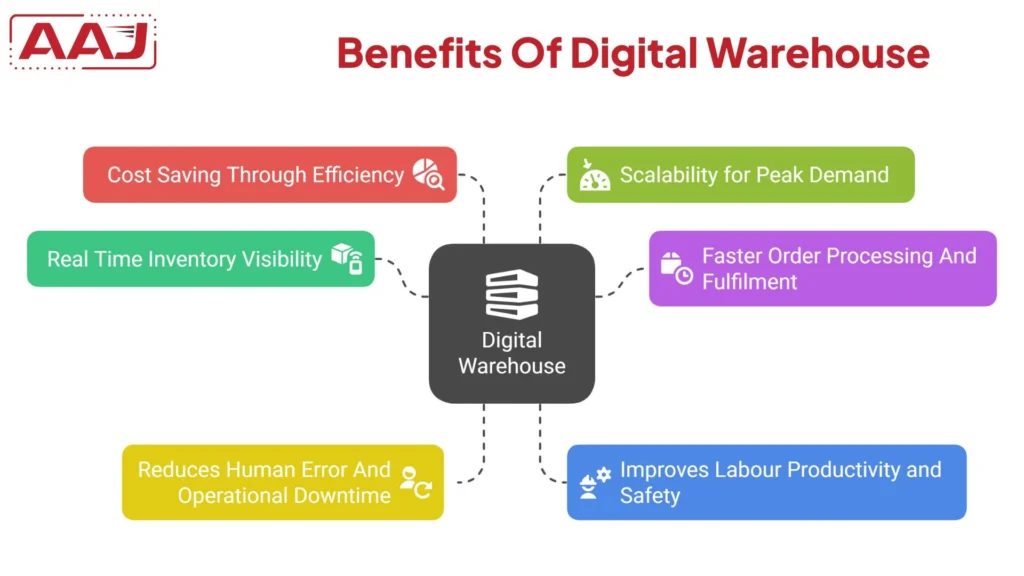

Benefits Of Digital Warehouse

The benefits of a digital warehouse are as follows.

1. Real Time Inventory Visibility

Digital warehouses use RFID tags, barcodes, and IoT sensors to track inventories in real time. It avoids problems of overstocking and out-of-stock issues.

2. Faster Order Processing And Fulfilment

Digital warehousing leverages automation and robotics, which enables order picking and packaging to be done faster. Thus, it helps to deliver ordered products faster to the customer and enhances brand reputation in the market.

3. Reduces Human Error And Operational Downtime

Automated systems in digital warehouses reduce human error and improve warehouse operations efficiency.

4. Improves Labour Productivity and Safety

Digital warehouses improve labour productivity by embracing automation. Robots do the repetitive tasks and lift heavy loads, reducing the chances of warehouse accidents.

5. Cost Saving Through Energy, Space, And Labour Efficiency

Automation in a digital warehouse optimises the warehouse space, which lowers energy costs. It even reduces dependency on manual labour.

6. Scalability for Peak Demand

A digital warehouse can scale up or down by adjusting its automation systems.

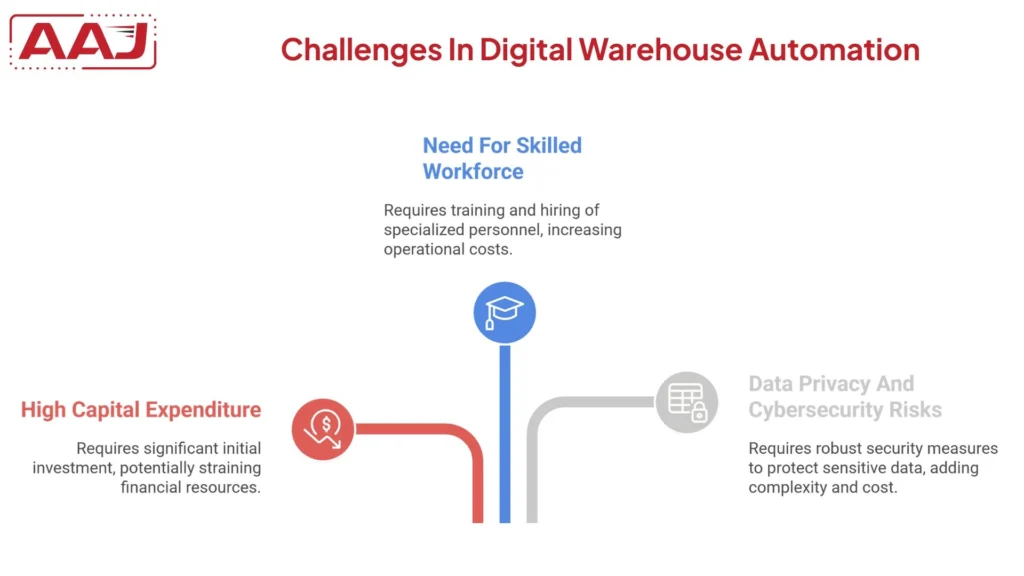

Challenges In Digital Warehouse Automation

1. High Capital Expenditure

Implementing robotics, advanced software, and automation systems requires a high initial investment, which is impossible for every small and medium enterprise.

2. Need For Skilled Workforce

Maintaining automation and advanced software in the digital warehouse requires a skilled workforce. Businesses need to educate their staff about AI, machine learning, cloud computing, and the use of advanced software.

3. Data Privacy And Cybersecurity Risks

Businesses maintain a vast amount of data through cloud systems. It increases the risk of data breaches and cybersecurity problems.

Digital Warehouse VS Smart Warehouse? Are They Different?

Digital warehouses and smart warehouses are related to each other. But they are not precisely the same. Digital warehouses use warehouse management systems, cloud computing, and data analytics to manage warehouse operations.

Smart warehouses are an advanced version of digital warehouses. It uses AI and robotics to automate the warehouse fully.

Final Words

Digital warehouses have become necessary for businesses to thrive in this competitive environment. It fulfils orders faster and improves customer satisfaction. Simultaneously, it enhances safety in the warehouse, which was lacking in traditional warehouses.